This post will serve as an Ultimate Guide for Initial S4 Settings to Configure EWM.

In this post we will do the required initial settings in S4 HANA or ERP depending upon the deployment options as explained below

- S4 HANA Embedded EWM – Setting explained in this post needs to be done in the same system.

- Decentralized EWM on S4 HANA – Setting explained in this blog needs to be done in S4 HANA system connected with Decentralized EWM on S4 HANA system.

- SAP EWM 9.5 (or lower versions) – Setting explained in this blog needs to be done in ERP/ECC system connected with SAP EWM.

Table of Contents

1. Warehouse Configuration & Assignment to Plant & Storage Location

Through this configuration, SAP S/4HANA recognizes which storage locations is controlled by which Warehouse Management system.

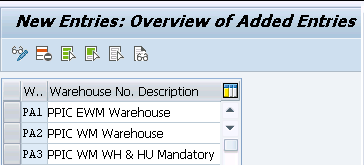

1.1 Warehouse configuration

In ECC/S4 HANA, warehouse number is 3 characters whileIn EWM, warehouse number is 4 characters.

For each EWM warehouse , we need to define a warehouse in ECC/S4/Embedded ERP.

We need two type of warehouses for our car business. One type will be simple traditional SAP WM and the other will be SAP EWM

SAP has offered a new solution for warehouse management with SAP EWM (Extended Warehouse Management). SAP EWM offers more customization options compared to SAP WM. We will configure below warehouses --> Warehouse PA1 (Corresponding to EWM WH PA10) for the below options *ERP - if using SAP EWM 9.6 or below. *S4 - If using Decentralized EWM on S4 HANA. *Embedded EWM LE configuration - if using S4 HANA embedded EWM. --> Warehouse PA10 for EWM warehouse connected with the above warehouse PA1 --> Warehouse PA2 for SAP WM warehouse --> Warehouse PA3 for SAP WM warehouse with HU mandatory

Please check the below post for warehouse configuration

SPRO –> Enterprise Structure –> Definition –> Logistics Execution –> Define, copy, delete, check warehouse number

1.2 Storage Locations (SLOC)

For our car business warehousing needs, we will configure SLOCs as per the below.

For our car business we will use below type of Warehouse related activities.

--> PP20: SLOC with Warehouse Management (WM).

--> PP21: SLOC with Inventory Management (IM) & Handling Unit (HU) mandatory.

Please check below post for configuration & testing of PP21

SAP Storage Unit Management and Handling Unit Management

--> PP22: SLOC with Warehouse Management (WM) & Handling Unit (HU) mandatory.

--> PP1D: SLOC with EWM (Received on Dock)

--> PP1S: SLOC with EWM (Available for Sale)

--> PPSA: Production SLOC with EWM

Please check the below link for SLOC details and configuration

Configure SAP S4 HANA Material Management Organization Structure in 5 Minutes

Note : Since WM is now going to be obsolete so we will not configure WM now and use WM managed storage locations (PP20 & PP22) for other use. For example-we will use PP20 SLOC now as a IM HUM partner SLOC

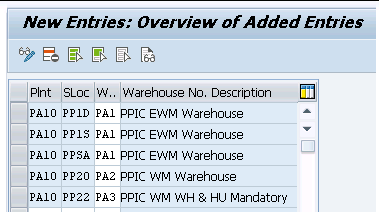

1.3 Assignment of WH to SLOC

Now we will assign the SLOCs to WHs as per the functionality of warehousing required (WM/EWM/HU mandatory etc.)

Note

- Since WM is now going to be obsolete so we will not configure WM.

- So We will use WM managed storage locations (PP20 & PP22) for other use.

- For example-we will use PP20 SLOC now as a IM HUM partner SLOC

2. Handling Unit Management

Now we will configure Handling Unit management in S4/ERP side

2.1 Define Packaging Material Type.

Check the below post for packaging material type configuration. We have configured several packaging material types for our car business.

SAP Storage Unit Management and Handling Unit Management

2.2 Define Material Group for Packaging Material.

Check the below post for packaging material type configuration.

SAP Storage Unit Management and Handling Unit Management

2.3 Define Allowed Packaging Materials.

Check the below post for packaging material type configuration.

SAP Storage Unit Management and Handling Unit Management

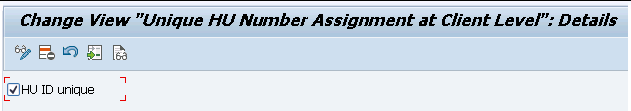

2.4 Set Unique Number Assignment for HU Identification

Here assignment of handling unit identification is set as unique in this client.

Please note that to manage a storage location as HU-managed is not possible without setting this indicator. Also, a link from handling unit to storage unit is not possible if unique number assignment is not assured.

SPRO –> Logistics – General –> Handling Unit Management –> External Identification –> Set Unique Number Assignment for HU Identification

2.5 Configuration of SSCC Generation Acc. to EAN128

Check the below post for Configuration of SSCC Generation According to EAN128.

SAP Storage Unit Management and Handling Unit Management

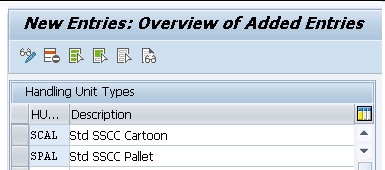

3. Define Handling Unit Type

HU types in Extended Warehouse Management are required to classify packaging materials and HUs with the same physical properties.

SPRO –> Integration with Other SAP Components –> Extended Warehouse Management –> Additional Material Attributes –> Attribute Values for Additional Material Master Fields –> Define Handling Unit Type

We have defined the below HU type for our car business

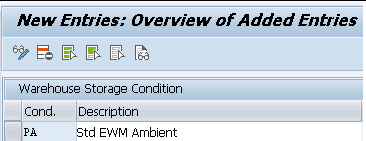

4. Define Warehouse Storage Condition.

We need warehouse storage conditions in Warehouse Management to specify that a material should only be stored under particular storage

conditions, for example, at a specific temperature.

SPRO –> Integration with Other SAP Components –> Extended Warehouse Management –> Additional Material Attributes –> Attribute Values for Additional Material Master Fields –> Define Warehouse Storage Condition

We have defined below WH storage condition

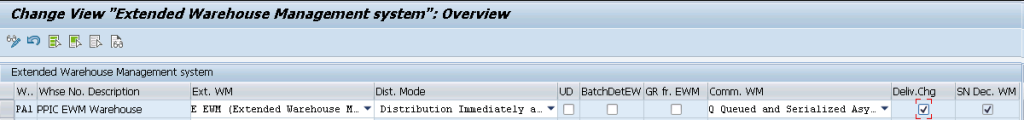

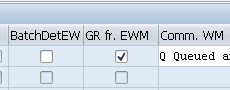

5. Configure SAP EWM-Specific Parameters

The Warehouse Management system in SAP S/4HANA is activated by assigning the plant/storage location to the warehouse number.

If this warehouse number is created because of a corresponding EWM system then it needs to be set to SAP S/4HANA with EWM.

So for example PA1 WH is created in S4/ECC because of PA10 EWM so this WH is required to be set in this configuration

SPRO –> Logistics Execution –> Extended Warehouse Management Integration –> Basic Setup of Connectivity –> Configure SAP EWM-Specific Parameters

Note: There is a very important settings here for EWM-Production integration. The below setting from the “Configure SAP EWM-specific Parameters” is very helpful in finished products receipt from production.

--> If the absence of this indicator, Inbound deliveries can be generated for the same production/process order parallelly from both ERP & EWM, resulting in over delivery for the order. --> With this indicator set, inbound deliveries can only be generated production/process order from EWM only

6. Assign Warehouse number to EWM Warehouse Number

Here we assign the warehouse number of the decentralized SCM system to the warehouse number of the ERP system.

SPRO –> Integration with Other SAP Components –> Extended Warehouse Management —> Assign Warehouse Number to EWM Warehouse Number

Note: We need this assignment to select the materials required in EWM during distribution of the material master data. This is not mandatory for embedded EWM. It is not required now in Decentralized S4 HANA too as material master is distributed through ALE/IDOC and BP through DRF.

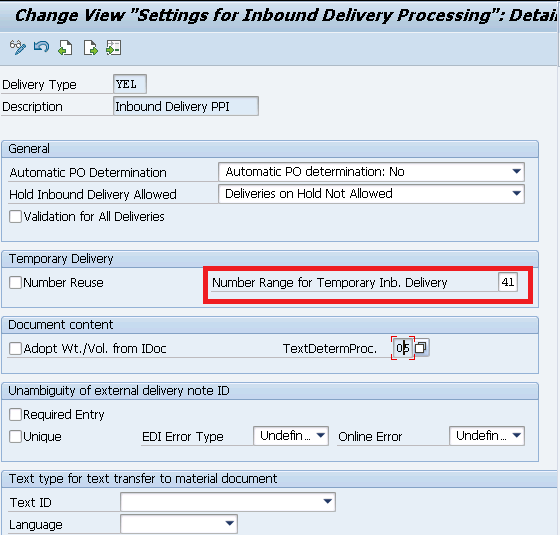

7. Setting for Inbound Delivery processing

In the setting we will configure below for temporary inbound delivery

–> Activate re-usage of numbers for temporary inbound deliveries

–> Assign a number range for temporary inbound deliveries

We have created inbound delivery as “YEL” for our car business.

Please see the below post for configuration of IBD type “YEL”

Configure SAP S4 HANA Sales Documents in 10 Minutes

we will assign the same number range “41” to YEL as temporary here

7.1 Temporary Inbound Delivery

If the inbound delivery has to be processed by SAP EWM, SAP S/4HANA creates a temporary inbound delivery when any changes or deletions are made. The system sends a message to SAP EWM for acknowledgement by the latter. When SAP EWM returns the acknowledgement, SAP S/4HANA deletes the temporary inbound delivery and the changes are made (positive acknowledgement), or not (negative acknowledgement/rejection).

SPRO –> Logistics Execution –> Extended Warehouse Management Integration –> Extended Inbound Delivery Processing –> Settings for Inbound Delivery Processing

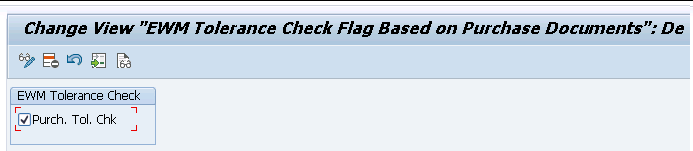

8. EWM Tolerance Check Indicator Based on Purchasing Documents

Here it is determined whether the tolerance check to be performed in EWM will be based on purchasing documents or will be delivery-based.

SPRO –> Logistics Execution –> Extended Warehouse Management Integration –> Extended Inbound Delivery Processing –>EWM Tolerance Check Indicator Based on Purchasing Documents

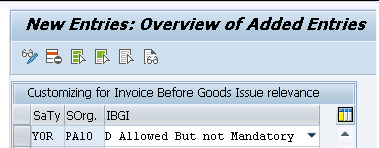

9. Set Invoice before Goods Issue for Billing Documents

Invoice is created after goods issue. However for international transportation we may require the invoice printout before the end of the loading and transportation process. Through this setting we can create the current invoice before goods issue posting.

We can request an invoice for each delivery or one or more invoices for the contents of a vehicle or transportation unit.

SPRO –> Logistics Execution –> Extended Warehouse Management Integration –>Billing Settings –> Determine Invoice Before Goods Issue (IBGI) Indicator

Here we need to do this setting based on our sales document type & sales organization

For our car business, sales document type configuration in detail, please check the below post

Configure SAP S4 HANA Sales Documents in 10 Minutes

For our car business, sales org configuration in detail, please check the below post

Configure SAP Sales & Distribution Organization Structure in 5 Minutes

10. Define Default Values for Deliveries

Transfer posting from non-WM SLOC managed to WM managed SLOC with in a same plant is done through deliveries. Here we define the default values that should be used for deliveries for each warehouse number.

We define the following parameters at the warehouse number level

- Inbound deliveries: Supplier

- Outbound deliveries: Ship-to party, shipping point, sales organization, distribution channel, and division

SPRO –> Logistics Execution –>Decentralized WMS Integration –> Central Processing –> Application –> Inventory Management Interface and Delivery-Relevant Data –> Define Default Values for Deliveries

Note : Ship to party and supplier will be created and filled later.

Tip

If our warehouse is mapped to multiple plants then we want to assign this to plant level instead of warehouse level.

To do so we can create different ERP warehouse numbers for each plant and these ERP warehouse numbers can be assigned to same EWM warehouse number.

When you create transfer posting delivery, plant specific ship to party and supplier will be considered in the delivery.

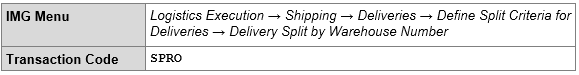

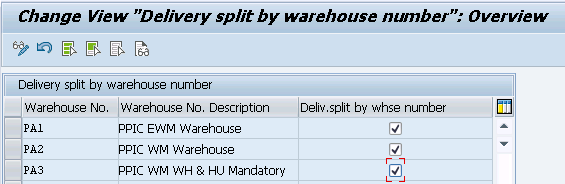

11. Delivery Split by Warehouse Number

Here deliveries created for a specific warehouse is split and created automatically in the corresponding warehouse based on the storage location.

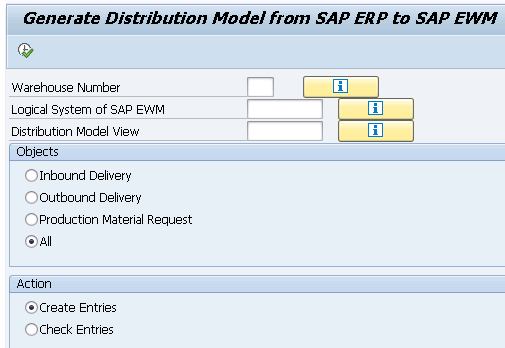

12. Generate Distribution Model for Transaction Data Transfer to SAP EWM

Here we generate the distribution model to distribute the objects (Inbound deliveries, outbound deliveries, PMR etc.) from central SAP S/4HANA system to one or more SAP EWM systems by qRFC.

These objects include inbound deliveries, outbound deliveries, and production material requests.

Note: Setting given as serial number 5 is mandatory to complete before doing this activity. Click on the link below.

Configure SAP EWM-Specific Parameters.

Go to below path

SPRO –> Logistics Execution –> Extended Warehouse Management Integration –> Basic Setup of Connectivity –> Generate Distribution Model for Transaction Data Transfer to SAP EWM

- Enter our Warehouse number PA11

- Enter the logical system name of the SAP EWM system. Please click HERE to check how EWM system logical name was created.

- Enter a name for the distribution model. If it is an existing distribution model, enter the existing name.

- Specify all objects

- Specify that we want to create entries for the distribution model.

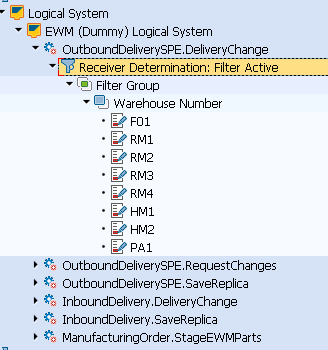

Below objects will be created

| Object | Method |

|---|---|

| OutboundDeliverySPE | SaveReplica |

| OutboundDeliverySPE | DeliveryChange |

| OutboundDeliverySPE | RequestChange |

| InboundDelivery | SaveReplica |

| InboundDelivery | DeliveryChange |

| ManufacturingOrder | StageEWMParts |

This completes the S4/EWM related configuration for EWM

In the previous post we have configured S4 HANA EWM system connection basic settings in 3 Easy Steps. Click on the above link to read in detail.

In the next post we will configure Basic integration settings related to the S4 HANA Embedded/Decentralized EWM. Click on the above link to read in detail.

Digital communication photo created by onlyyouqj – www.freepik.com