In this post we will see in detail how to Configure Batch Search Strategy for Production Order.

Table of Contents

1. Production Order Creation

We need to create production order to check how to Configure Batch Search Strategy for Production Order.

Please see the below post to know in detail how to configure the production order

How to Configure Base PP Cycle in 5 Minutes

We have created production order 1900074 to test how to configure Batch Search Strategy for Production Order

Please see the below post to see the creation of production order 1900074 and associated BOM in details.

Material Staging for Production-Production Order Creation

2. Material Staging

Now material staging needs to be executed so that components batches are available for production order to be picked.

In the post given below we have executed the production order material staging. That mean components required for production are successfully transferred to the production supply storage location.

Material Staging for Production

Now our production order created in step 1 require the below components in the respective quantities

This stock is required at production SLOC.

Below is the situation of stock at production SLOC (PP1B)

Material Staging for Production-Stock Situation after Staging Execution

Now there can be two actions to proceed further Option 1) Select the batches for the components to be issued to production order manually Option 2) System selects the components batches to be issued to production order automatically through batch search strategy.

In this post we will see the option 2

3. Production order Batch Search Strategy Execution Preparation

We have configured batch search strategy in the below post. Please visit the link and see the step by step configuration in detail

How to Configure Batch Search Strategies in SAP-Batch Search Strategy in Production Order

--> In the above Configuration we have created a production Order batch search strategy which will pick the batches as per remaining shelf life with least remaining days batch among others will be picked first. But this batch will have remaining shelf life equal to or more than certain days

3.1 Creation of search strategy for Component 1 (500000019)

Batch search strategy will selected the batches with remaining shelf life more than or equal to 50 days

Since sorting rule is ascending, so out of selected batches (having sort life>=50 days), the batch having least SLED will be picked first.

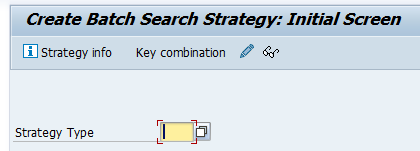

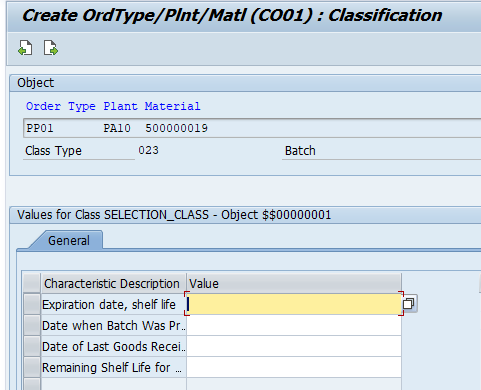

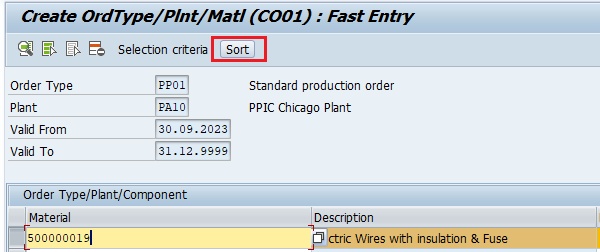

Run COB1

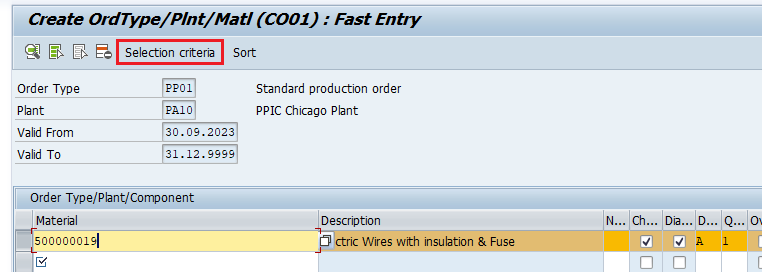

Enter strategy type as “CO01”

Input the order type as “PP01”, plant as “PA10” and material as “500000019”, Press enter

Select the material line as shown in the above screenshot and click on “selection criteria”

System will present screen to input the selection criteria. Please see the screenshot below

Note: This screen is coming from the selection class and associated characteristics

Please see the details in the below post

How to Configure Batch Search Strategies in SAP-Selection Classes

Input the batch selection criteria as required (SLED >=50 Days)

Come back and click on “Sort”

3.2 Creation of search strategy for Component 2 (500000021)

Batch search strategy will selected the batches with remaining shelf life more than or equal to 17 days

Since sorting rule is ascending, so out of selected batches (having sort life>=17 days), the batch having least SLED will be picked first.

Repeat the steps for the material 500000021 given in the heading 3.1

Pay attention to input selection criteria as SLED>=17

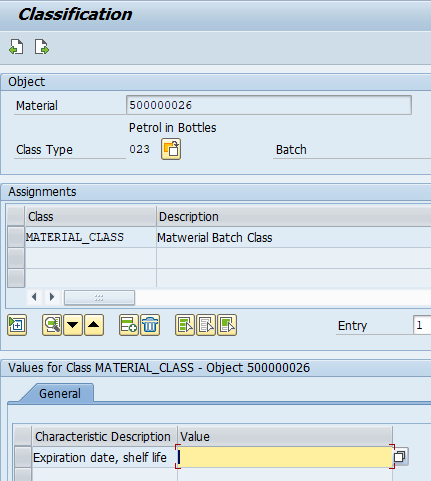

3.3 Creation of search strategy for Component 3 (500000026)

Batch search strategy will selected the batches with remaining shelf life more than or equal to 90 days

Since sorting rule is ascending, so out of selected batches (having sort life>=90 days), the batch having least SLED will be picked first.

Repeat the steps for the material 500000026 given in the heading 3.1

Pay attention to input selection criteria as SLED>=90

3.4 Creation of search strategy for Component 4 (500000009)

Batch search strategy will selected the batches with remaining shelf life more than or equal to 100 days

Since sorting rule is ascending, so out of selected batches (having sort life>=100 days), the batch having least SLED will be picked first.

Repeat the steps for the material 500000009 given in the heading 3.1

Pay attention to input selection criteria as SLED>=100

3.5 Sorting Rule

We have used sorting rule as “123” in our strategy creation as described in the below post

How to Configure Batch Search Strategies in SAP-Sorting Rule

3.5 Material Batch Class (023)

Once assigned to the material master , this class will be valid for all the batches of the materials.

So all the batches received will be valuated through the characteristics of this class.

we will use material class as “MATERIAL_CLASS” as given in the below post in detail.

How to Configure Batch Search Strategies in SAP-Material Classes (Type-023)

3.5.1 Material Master Data Classification Update

Please make sure that material batch class “MATERIAL CLASS” is inputted in the material master classification view for all the four comonents

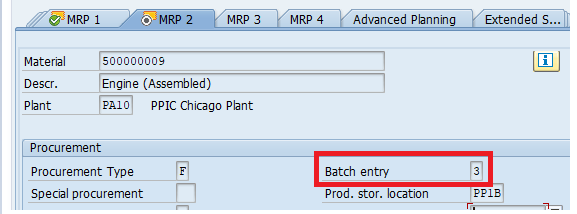

3.5.2 Material Master Data “Batch Entry” Settings Update

Go to MM01 and make sure that entry in the field “Batch Entry” is selected as “3-Automatic batch determination upon release of order”

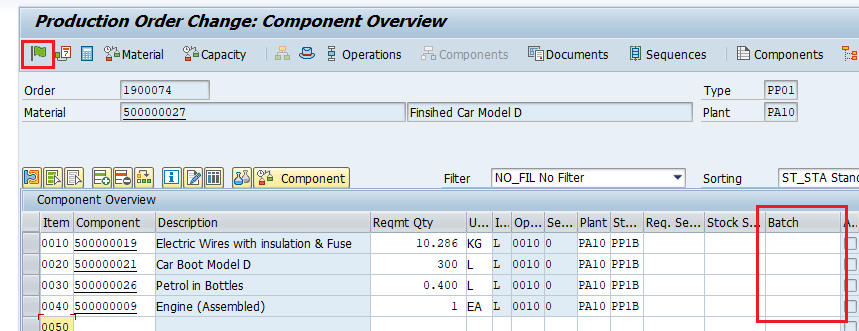

4. Production order Batch Search Strategy Execution

Now we will execute the batch search strategy in production order

Since our sorting rule is to sort SLED ascending order so we will first check what batch system should pick,

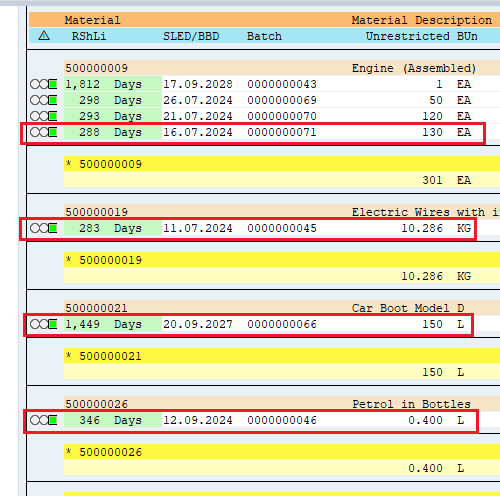

4.1 Stock in SLED Ascending

Run MB5M on SLOC PP1B.

System will list all the available stock in remaining SLED ascending order.

See the below screenshot of MB5M.

--> System should pick the above highlighted batch for each material upon running the batch search in production order.

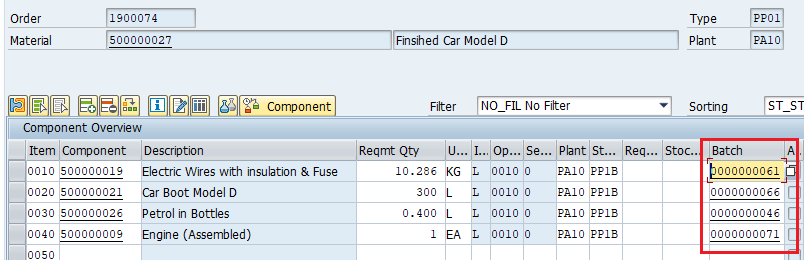

Now release the production order and check what batch system has chosen to pick

System has picked the batches are per the expectation

With this production order batch search strategy configuration ends.