SAP Sales Item Categories are a critical components within the SAP Sales and Distribution (SD) module which defines how different materials are processed in various sales documents.

Sales Item categories determine the behavior of items, ensuring that each material is handled appropriately based on its specific characteristics and the business requirements in the sales orders, quotations, and deliveries,

item categories are configured to control pricing, delivery schedules & billing. Efficient configuration leads to enhanced efficiency and accuracy in sales processes.

--> Item Category is used in sales order as well as in delivery.

--> If we create or copy a new item category for delivery, we must also define a delivery item category for the sales order with the same name. The system automatically transfers the item category that was found for the sales document item into the delivery item.

Table of Contents

1. Configuration of Item Categories

The sales item category is one of the most important fields in the SAP sales order. It controls the sales document flow and also impacts the schedule line category

Item Category realize different business processes for each item in the sales document.

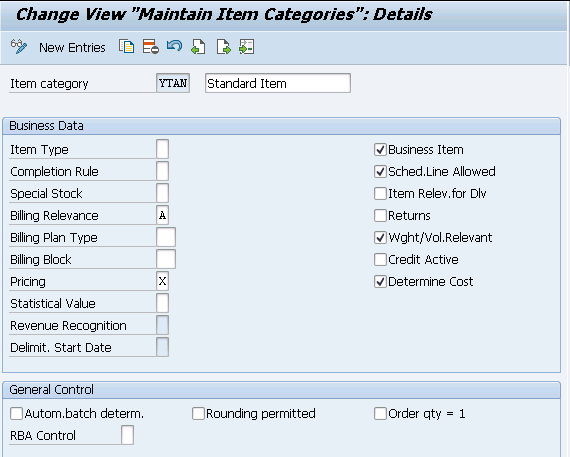

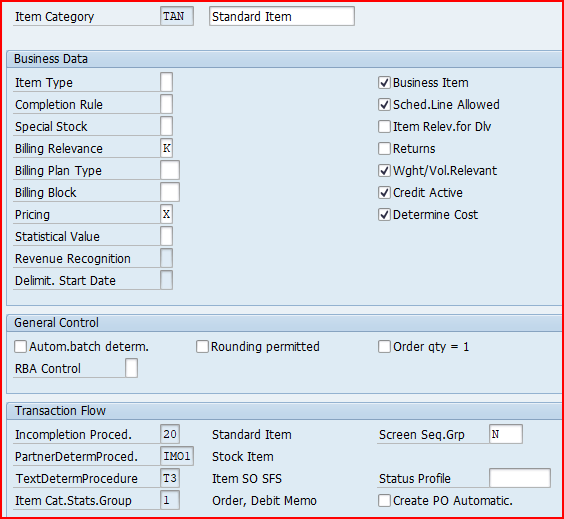

Item Category decided below behavior of the materials in the sales documents. Let’s review all the fields controlled by Item category one by one

- Relevance for billing of an item – The value determines what kind of billing document it has to generate for this item. That is order related billing document or delivery related billing document.

- Billing block – The billing block indicator is used to block each item of this category for billing.

- Pricing relevance – It indicates whether the system automatically carried out pricing for this item.

- Business data relevance item -It allows the business data at header level differs with item level business data.

- Schedule line allowed – It indicates whether we can create schedule lines for the item.

- Item relevant for delivery -It indicates whether a text or value item is relevant during delivery processing. The item itself is not delivered. But it serves only for information purpose in delivery documents.

- Returns – It indicates the item is return item

- Determine cost – This indicator enables the system to calculate cost of the material of this item category (condition type VPRS is used to calculate the cost price).

- Credit active – This indicator enables to configure credit management functions for this item.

- Incompletion procedure – We will configure Incompletion procedure in IMG and assign to item category. System reminds the end user if he does not maintain any values at item category level in the sales document.

- Partner determination procedure – This decides at item level and decides itself sold to party, ship to party, bill to party or payer for this item.

- Structure scope (relevant for bill of material explosion) – The value of this field determines whether the item is a BOM item. If it is so, how it should be exploded.

- Value contract material – The system copies value contract item that we specified here into the value contract.

- Contract release control – Here we can specify the system responses when the target value of value contract has been reached while releasing the contract.

We will configure below Item Categories for our car business sales documents.

1.1 Item Category of Sales Documents

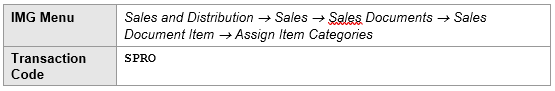

To configure the item category of sales document , follow the below path

1.1.1 Item Category for Standard Sales Order “TAN”

We will use SAP standard Item Category “TAN” for the standard sales order.

1.1.2 Item Category for Third Party Subcontracting Order “TADS”

A third-party subcontracting order involves outsourcing specific tasks or services to an external vendor who directly delivers the required goods or services to the end customer.

Third party subcontracting process streamlines operations, reduces costs, and enhances efficiency by leveraging the expertise and resources of specialized subcontractors

Please check the below post for 3rd party subcontracting process configuration & testing in detail

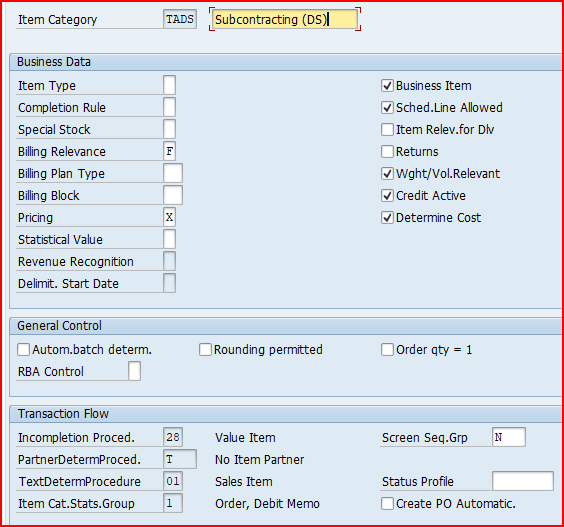

Item category “TADS” is used for 3rd party subcontracting process.

Lets see the configuration of TADS

Please note that billing relevance is “F-Order-related billing doc. – status according to invoice qty” instead of “A-Delivery-related billing document”

1.1.3 Item Category for 3rd Party Process.

In the third party Order process , final product is outsourced to a third party to sell it to customer.

There are various scenarios for the third party. Lets see each third party scenario item category requirements

a) Item Category for 3rd Party sales “TAS”

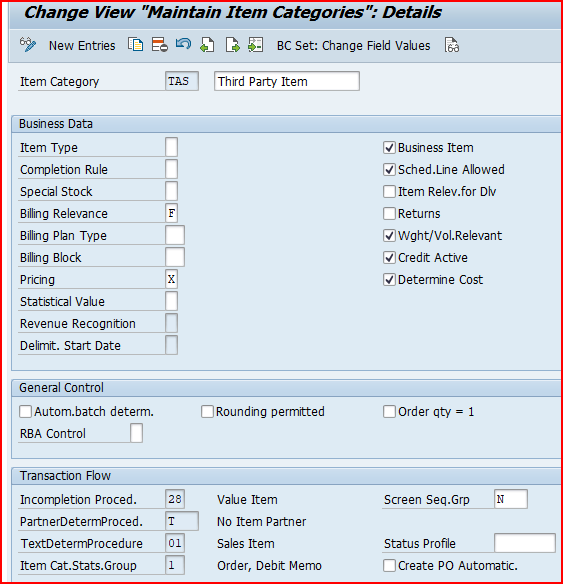

For the third-party order processing, the item category is TAS.

Please note that billing relevance would be configured as “F”. It is because of Order related invoice will be created here. The delivery will not be done from our premises. It will be sent straight from the third party to the customer.

If relevance for billing indicator for the item category is “B” (relevant for order-related billing on the basis of the order quantity), the system includes the order in the billing due list immediately. Hence the third-party order is considered to be completely billed only when the vendor invoiced quantity equals the order quantity of the sales order item.

If relevance for billing indicator set to F (relevant to order-related billing on the basis of the invoice quantity), the system does not include the order in the billing due list until an vendor invoice is received and processed. Each time a vendor invoice is received, a customer invoice is created for the quantity in the vendor invoice and the order is considered to be fully invoiced until the next vendor invoice is received.

So if billing-relevance indicator F is activated for item categories, billing can refer to the goods receipt quantity instead of the incoming invoice quantity.

b) Third-party with individual Purchase Orders “TAB”

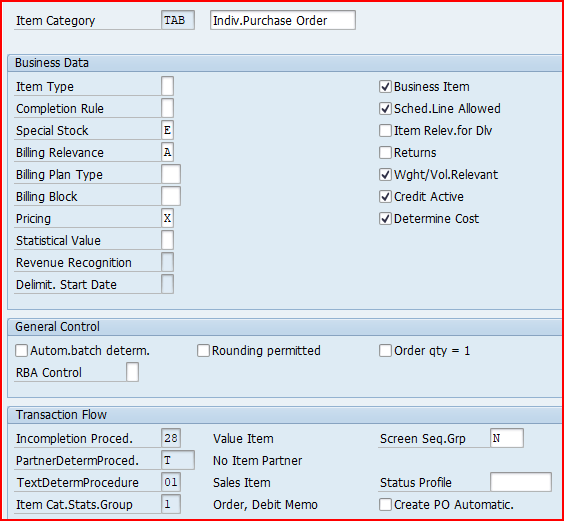

For the third-party with individual Purchase Orders processing, the item category is TAB.

Please note that here billing relevance would be A as the finish material will be received first in our stock/warehouse. from our warehouse it will be delivered to the customer.

Value “A” in the billing relevance item category of sales order indicates that the billing document is created based on the delivery. This means that the invoice is generated after the goods have been delivered to the customer.

c) Third-party with Automatic PO Creation “ALES”

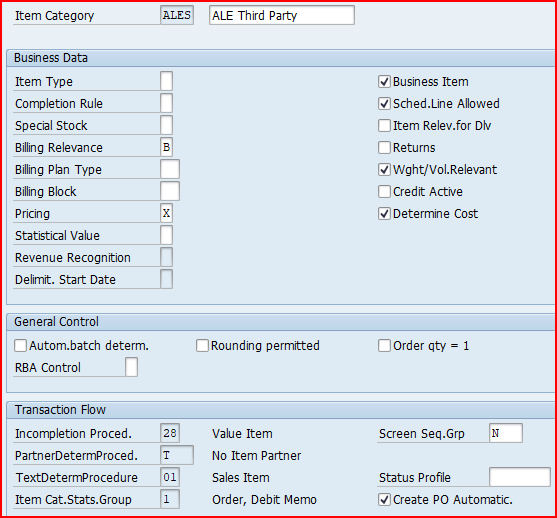

For the third-party with individual Purchase Orders processing, for the ALE process (automatic order creation) the item category is ALES.

2. Item Category Determination in Sales Documents

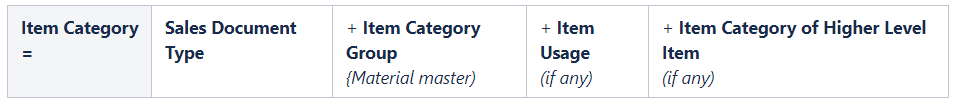

Item category group field of the material master is the main factor to determine the item category in the sales order. This indicator + Sales document type + usage of the item category + Item category of higher-level item

decides the item category in the sales order document.

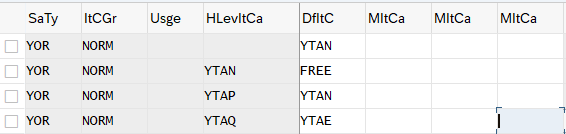

2.1 Item Category Determination for Std. Order

Item category is determined as per below combination in sales documents

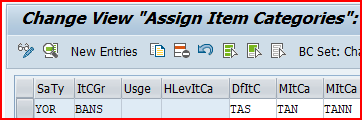

We have configured our item categories as below

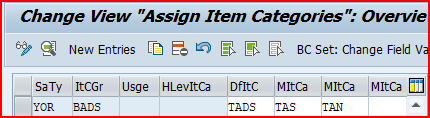

2.2 Item Category Determination for 3rd Party Subcontracting

for third party subcontracting order we use Item category as “TADS” as described HERE

From the above configuration, Item category TADS will be determined automatically for sales order type YOR and item category group BADS (third-party subcontracting item)

Please note that Item category group “BADS” comes from the material master as explained in the below post

2 Minutes Guide to Create your First Material in S4 HANA – “Gen. item cat. grp” for Third Party Subcontracting

2.3 Item Category Determination for 3rd Party Process

As we have seen HERE , there are three scenarios for third party process in SAP

- Item Category for 3rd Party sales, Item category “TAS” is used.

- Third-party with individual Purchase Orders, Item category “TAB” is used.

- Third-party with Automatic PO Creation, Item category “ALES” is used.

2.3.1 “TAS” Determination

Item Category “TAS” is determined as per below configuration

Please note that Item category group “BANS” comes from the material master as explained in the below post

2 Minutes Guide to Create your First Material in S4 HANA – “Gen. item cat. grp” for Third Party Sales

Please check the detail step by step end to end third party process in the below post

The Ultimate Guide to SAP Third Party Sales

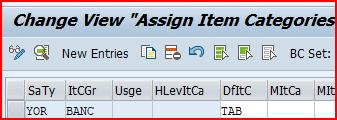

2.3.2 “TAB” Determination

Item Category “TAB” is determined as per below configuration

Please note that Item category group “BANC” comes from the material master as explained in the below post

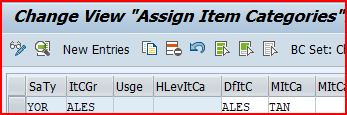

2.3.3 “ALES” Determination

Item Category “ALES” is determined as per below configuration

3. Item Category in Deliveries

Item categories are defined to have more control over individual materials in the deliveries. The item category is copied from an order item. A standard item in a standard order then becomes a standard item in the delivery. If a delivery is entered without reference to an order, the system proposes the item category depending on the delivery type and the item category group of the material.

Some Rules of Delivery Item Categories

--> When a sales order item is copied to a delivery, item category of the order item is copied to the delivery item. If order item or the schedule line assigned to order item is relevant for delivery a corresponding item category must be defined for the delivery.

--> Delivery item category key must be the same key as order item category. So we must define all delivery item categories as sales item categories in Sales and Distribution even for inbound delivery item category which is never found in sales documents. This is required for the system to create a copying relationship between the order and delivery document at the item level. For example DL/ELN to EL/ELN.

--> For all delivery item categories other than SD document category 7, a schedule line categories consisting of movement type must be determined in sales & distribution.

--> Delivery item category with SD document category 7 can be specified with movement type directly in delivery item category.

3.1 Configuration of Delivery Item Category

Delivery Item Category configuration determines the below properties

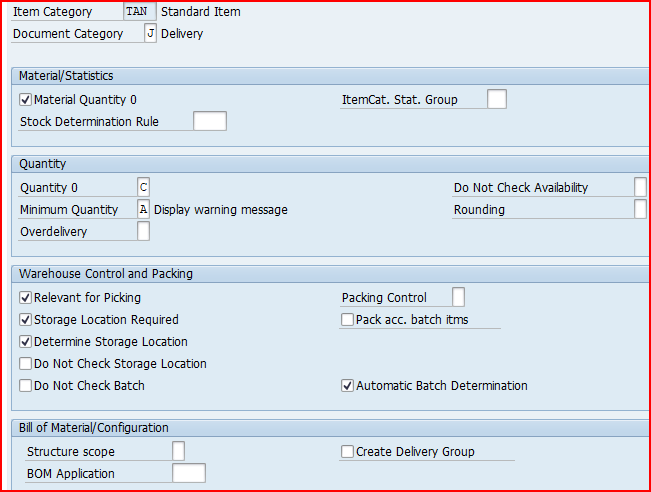

Let’s take the example of Standard Delivery Item category “TAN” & review all the fields which can be configured

- Document category : A classification for the different types of documents in the sales and distribution system

- Material number 0 allowed: It controls whether it makes sense to enter an item with this item category without specifying a material. It allows to create a delivery document for a line item with 0 quantity, Ex-Text Item.

- Item category statistics group: It specifies a statistics group for this item category and helps determine which data the system updates in the Logistics Information System.

- Stock determination rule: Stock determination rule and stock determination group are combined into one key for stock determination strategy. This is used in the repetitive manufacturing process.

- Check quantity : It specifies when we create an item that has a 0 quantity, how system should give message. It is useful for the items that are creating without order.

- Check minimum quantity : It specifies whether system has to check minimum delivery quantity as per customer material info/Material Master record. System gives warning or error message.

- Check over delivery : It specifies how the system reacts whether warning or error message during delivery processing when original order quantity exceeds delivering order quantity as per info record.

- Availability check off : It is the control to switch on/off availability check for delivery items.

- Rounding : This indicator specifies rounding rules for whole number unit of measure. It is useful for BOM items.

- Relevant for picking or put away: It indicates whether item of this type are relevant for picking or put away. In the outbound delivery process, only delivery items that are relevant for picking are transferred to the warehouse management. Service items and text items are not transferred to the warehouse.

- Storage location required: This indicator makes storage location as mandatory in the delivery document.

- Determine storage location: It indicates whether system has to determine storage location automatically.

- Do not check storage location: It indicates whether system should run a check for the storage location that was determined.

- No batch check: It specifies system checks the batch number that entered in the delivery document.

- Packing control: It indicates whether delivery items with this item category:

- May be

- Cannot be

- Must be packed

- Pack accumulated batch items: It specifies if for a batch material only the main item with accumulated batch quantity is to be packed in the delivery, or if only items in which the batch is recognized can be packed. Example -if total quantity is 20000 but it is manufactured in 20 batches, then all those 20 batches appear to be packed i.e. 20 line items of the same material to be packed. Through this indicator we can pack only 1 line item that is the sum of all the 20 batches, so that packing can be carried out more efficiently.

- Automatic batch determination: This indicator enables to determine batch automatically in the delivery documents.

Below Delivery Item categories are created for our business

3.1.1 Item categories for Outbound Deliveries

Follow the below path

a) Item Category for Standard Outbound Delivery

We use “TAN” for this

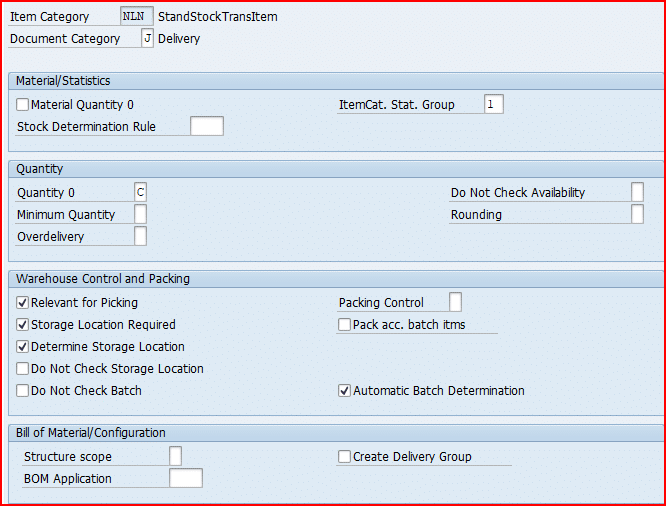

b) Item Category for Stock Transfer Order with Delivery

--> Stock Transport Order (STO) with Delivery is a SAP process to transfer the stock between two plants (or storage locations) within a company

Item category “NLN” is used for the one step/two step Stock Transfer Order with Delivery

Configure item category “NLN” as given in the below screenshot

Please check below post for Stock Transport Order (STO) with Delivery to see item category “NLN” usage

SAP Stock Transport Order with Delivery: A Complete Guide

c) Item Category for 1-Step Stock Transfer Order with Delivery

Item category “YNLN” is used for the 1-step Stock Transfer Order with Delivery

Configure item category “YNLN” as given in the below screenshot

Please check below post for 1-Step Stock Transport Order (STO) with Delivery to see item category “YNLN” usage

SAP Stock Transport Order

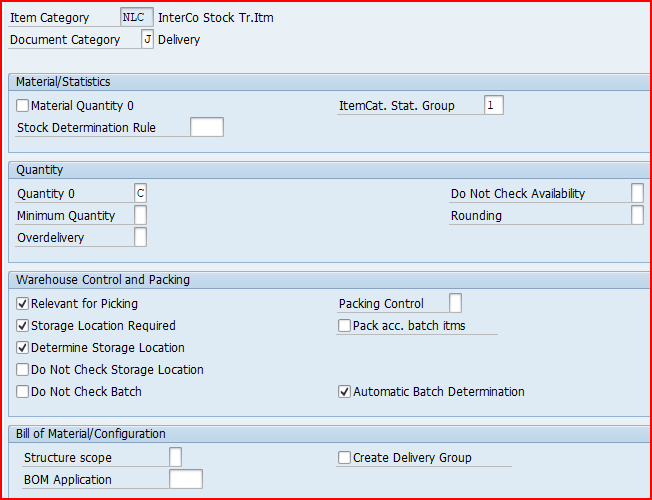

d) Item Category for the Inter-company STO Process with Delivery & Billing

Item category “NLC” is used for the the Inter-company STO Process with Delivery & Billing.

Configure item category “NLC” as given in the below screenshot

3.1.2 Item Categories for Inbound Deliveries

Please note that item category for inbound delivery needs to be maintained as a sales item category also, though item category will never have a sales order reference.

a) Reason of Inbound Delivery Item category configuration as sales document item category too.

For our car business inbound delivery, we will configure item category as “YELN”. We will define same item category key as “YELN” as a sales document item category also.

The reason for this is given below

--> Delivery item category key must be the same key as order item category. --> So we must define all delivery item categories as sales item categories in Sales and Distribution even for inbound delivery item category which is never found in sales documents. --> This is required for the system to create a copying relationship between the order and delivery document at the item level. For example DL/YELN to YEL/YELN.

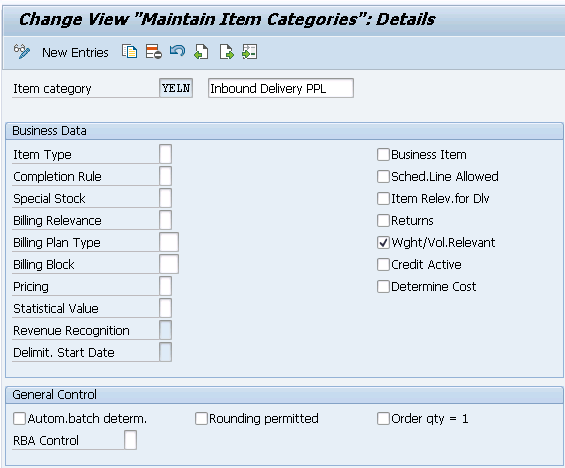

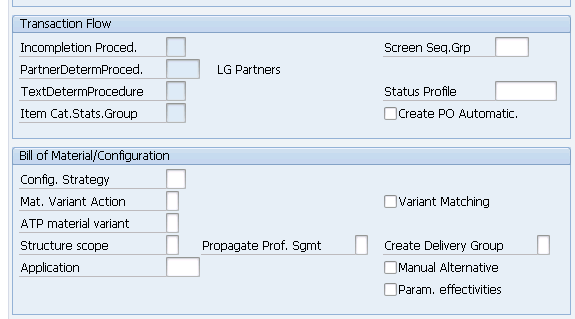

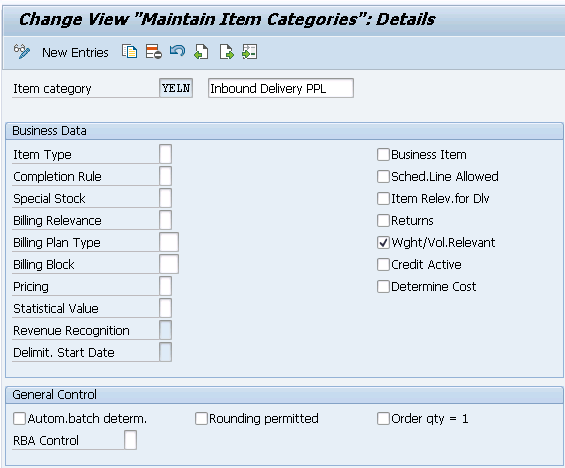

b) YELN – Item Category for Std Inbound Delivery (Sales Doc Item category Config)

Standard inbound delivery items which will follow standard inbound process we will configure item category as YELN.

Below is the configuration of all fields for standard item category YELN

Picture : Configuring Inbound Delivery Item category as sales document item category also Screen 2

Picture : Configuring Inbound Delivery Item category as sales document item category also Screen 2c) YELN – Item Category for Std Inbound Delivery (Delivery Item category Config)

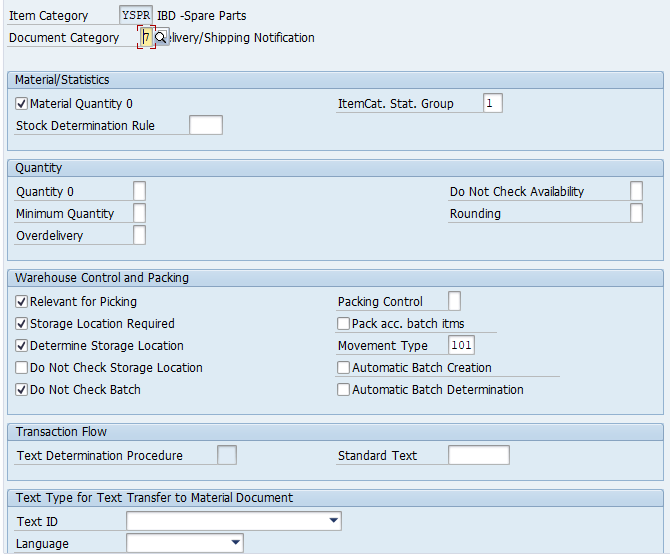

d) YSPR – Item Category for Inbound Delivery for spares

We have configured a special line item category for spares materials which will follow a special business process compare to the standard materials.

below is the configuration of YSPR line item category

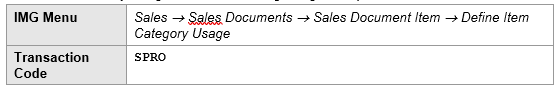

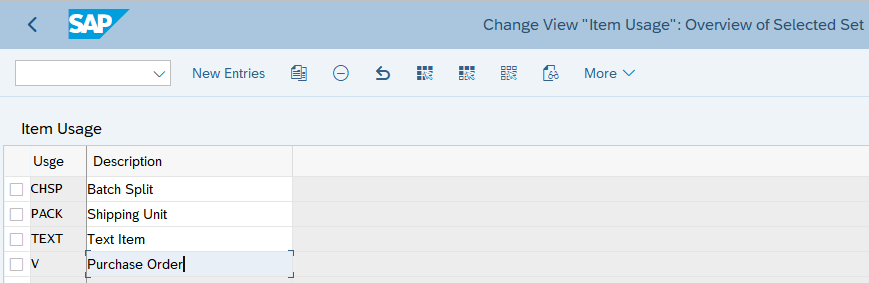

4. Define Item Category Usage

In this configuration, we specify the item category usages that control the usage of the item

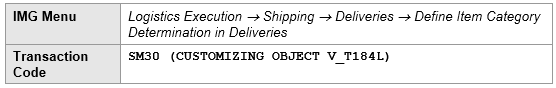

5. Determination of Item Categories in Deliveries

There are two ways of item category determination in deliveries

- Process where item categories are copied from the higher level sales order item. For example- Sales order to outbound delivery.

- For order-independent items in the delivery like packing material, or inbound deliveries. no item category can be copied from a sales order. In this case in addition to the delivery type & item category group from the material master, a special functionality called “usage” is also taken into account.

- Some example of usage -PACK for packing items, CHSP for batch split & V for for inbound deliveries for purchase orders and for deliveries in STOs.

Please note that in material master there are two fields. One is "General Item Category Group" which is at MARA level. This field is used for inbound deliveries The other field "Item Category Group" is used with sales organization & distribution channel in deliveries.

We will configure item category determination for normal customer outbound delivery, intra-company STOs outbound deliveries, intercompany STOs outbound deliveries & inbound deliveries.

below is the path to determine item categories in deliveries.

5.1 Determination of Item Categories in Outbound Deliveries

Item category is determined based on the below

- Item category group of the material

- Delivery Type

We will configure Determination of Item Categories in Outbound Deliveries one by one for all the scenarios

For our car business, we have configure determination of Item Categories in Outbound Deliveries as below

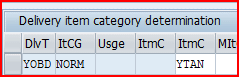

5.1.1 Item Category Determination for Standard Outbound Delivery

For standard delivery type “YOBD” & Item Category “YTAN” is used

We have configured Item Category Determination for Standard Outbound Delivery as per below screenshot

5.1.2 Item Category Determination for Stock Transfer Order with Delivery

for Stock Transfer Order with Delivery, Item category “NLN” & delivery type “NL” is used.

We have configured Item Category Determination for Stock Transfer Order with Delivery as per below screenshot.

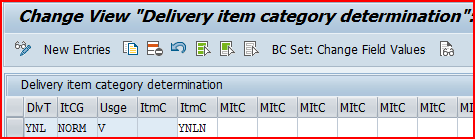

5.1.3 Item Category Determination for 1-Step Stock Transfer Order with Delivery

for 1-Step Stock Transfer Order with Delivery, Item category “YNLN” & delivery type “YNL” is used.

We have configured Item Category Determination for 1-Step Stock Transfer Order with Delivery as per below screenshot.

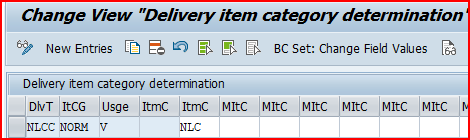

5.1.4 Item Category Determination for Inter-company STO Process with Delivery & Billing

for Inter-company STO Process with Delivery & Billing, Item category “NLC” & delivery type “NLCC” is used.

We have configured Item Category Determination for Inter-company STO Process with Delivery & Billing as per below screenshot.

5.2 Determination of Item Categories in Inbound Deliveries

We will configure the determination of Item Categories in Inbound Deliveries for all the business scenario

5.2.1 Item Category Determination in Standard Inbound Delivery

Below is the configuration of Item Category Determination in Standard Inbound Delivery

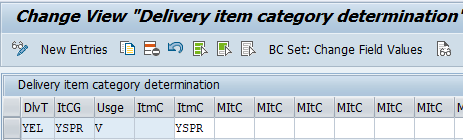

5.2.2 Item Category Determination in Special Process Inbound Delivery

Spare parts materials will follow a different process in inbound so we have configured a specific line item category YSPR for spare parts.

Below is the configuration of Item Category Determination in Special Process Inbound Delivery for spares

--> In the above item category determination different is the only Item category which comes from the material master. --> To determine different line item category "YSPR" for the spare parts materials from the the standard line item category "YELN", we have to input different "item category" in the material master of spare parts materials. Please check the below link to see this in detail 2 Minutes Guide to Create your First Material in S4 HANA-“Gen. item cat. grp” for Spare Parts Specific Business Purpose