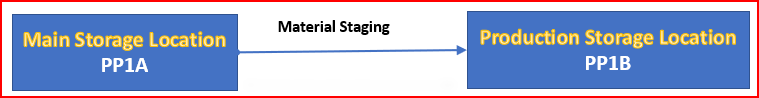

In a simple term, Material staging for production means transferring the materials from the main storage location to the production storage location.

--> Production Storage Location is the Production supply location or it is called "PSA (Production Supply Area)" also

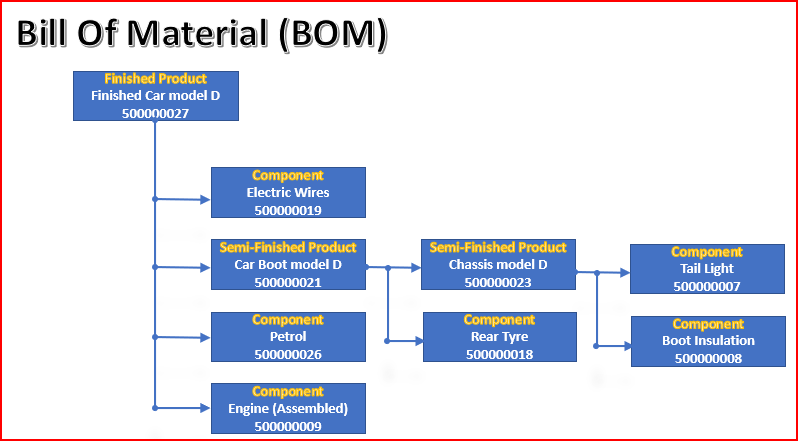

To manufacture the finished goods (FG) we may require Components (Raw Materials) as well as Semifinished goods (Assembly).

This is specified in Finish goods Bill Of Materials (BOM).

Table of Contents

1. Bill Of Material (BOM)

Below is the example of a Finished goods BOM

Please check the below post to know the FG BOM in detail and how to create FG as well as SFG BOMs

How to Configure Base PP Cycle in 5 Minutes-Create Bill Of Material (BOM)

1.1 FG BOM

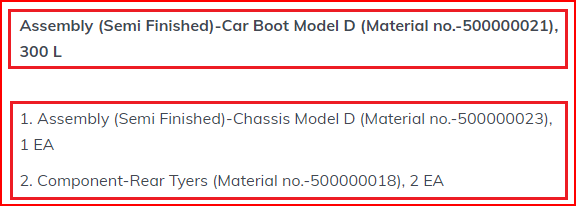

1.2 First Semi Finished BOM

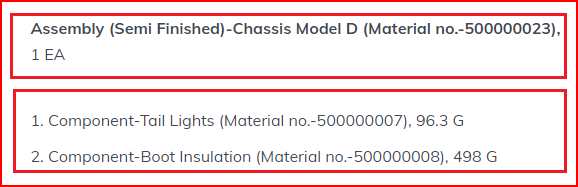

1.3 Second Semi Finished BOM

2. Production Material Staging -Concept

As we stated above to material staging means transferring the materials (require to produce) from the main location to production supply location

2.1 Main Storage Location

The main storage location is where material is stored.

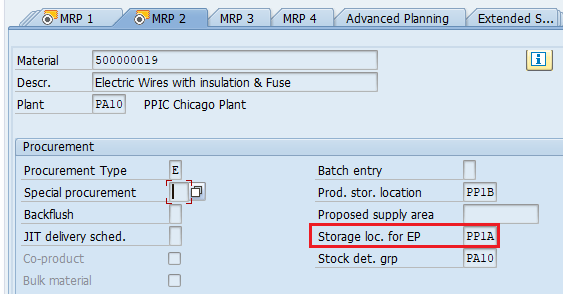

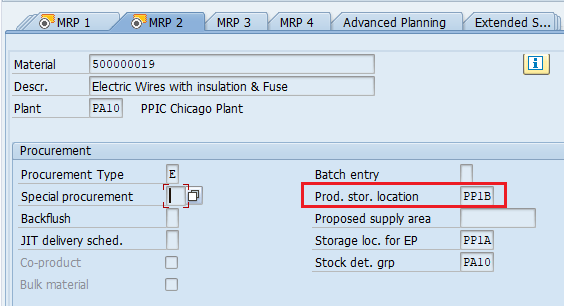

This is given in the “MRP 2” view of the material master

for our plants “PP1A” is the main Storage Location

2.2 Production Storage Location

The production storage location is from where material is supplied to production and received from production.

This is given in the “MRP 2” view of the material master

For our plant “PP1B” is the Production Storage location

Please see the below post to check the list of storage locations created for our plants and their respective usage

Configure SAP S4 HANA Material Management Organization Structure in 5 Minutes – Storage Locations for Various Scenarios

This is the simplest scenario for material staging. We will execute it through MF60

The other scenarios of Production Material Staging

- Production Material Staging with batch search strategy

- Production Material Staging with HUs

- Production Material Staging with WM – We will not explain this as WM is going to be obsolete with the EWM now mandatory with s4 HANA.

- Production Material Staging with EWM (Advance Production Integration)

3. Production Material Staging – Preparation

We will stage the material through pull list MF60

3.1 Salient Features of “Pull List”

Below are the main features of Pull list

- The pull list controls the flow of material for supplying to production with materials

- The pull list assumes that the components required for production are available at main storage location i.e. either they have already been produced in-house or procured externally.

- The pull list checks the stock situation at the production storage location and calculates the quantities of missing parts

- if all condition satisfies then pull list transfer the components from their current storage location or bin to the production storage location.

We will produce FG “Car Model D” which has 3 components & 1assembly

Please see the details HERE

Since Assembly is produced in house so it will be already available at production SLOC PP1B so there should not be any staging for this.

The rest of the three Components should be available at standard location PP1A and should be transfer to production SLOC PP1B through material staging i.e. here pull list

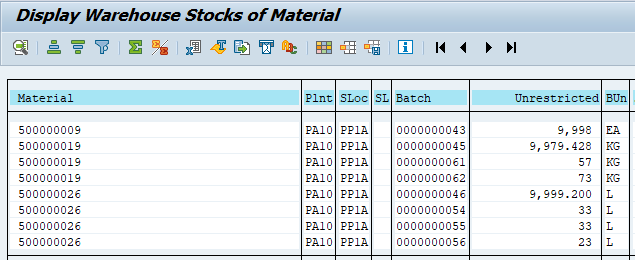

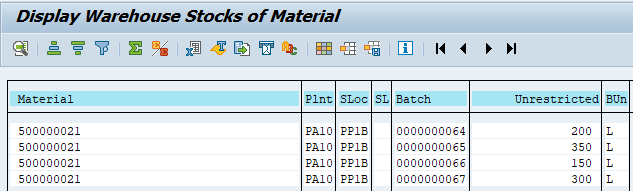

3.2 Components Stock at Standard SLOC

Stock of Components at Standard SLOC i.e. PP1A

3.3 Components Stock at Production SLOC

Below is the stock of components at production SLOC

--> Since only Assembly (SFG) is available at production SLOC (due to in-house production), pull list is expected to transfer the rest of three components in required quantity from the standard SLOC to Production SLOC

3.4 Stock Determination

This automatic transfer from the standard storage location to the production storage location is performed based on the stock determination strategy.

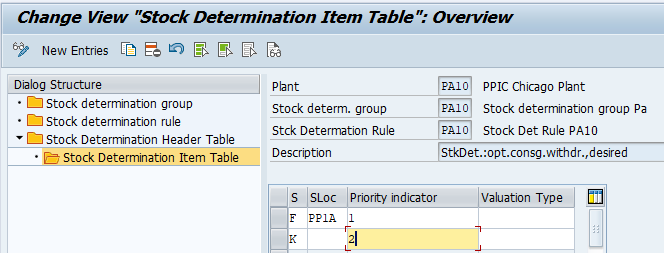

We will now customize all the components of the stock determination

3.4.1 Define Strategies for Stock Determination

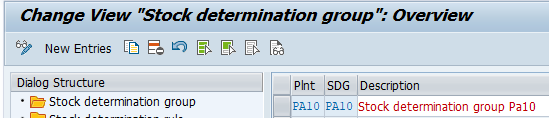

We define stock determination strategy using stock determination group and the stock determination rule.

The stock determination strategy at plant level is determined using the stock determination group and the stock determination rule

Follow the below path to configure stock determination strategy

SPRO –> Material Management –> Inventory Management and Physical Inventory –> Stock Determination –> Define Strategies for Stock Determination

We will configure stock determination group first

3.4.1.1 Stock Determination Group

We have configured stock determination group as “PA10” for our plant PA10

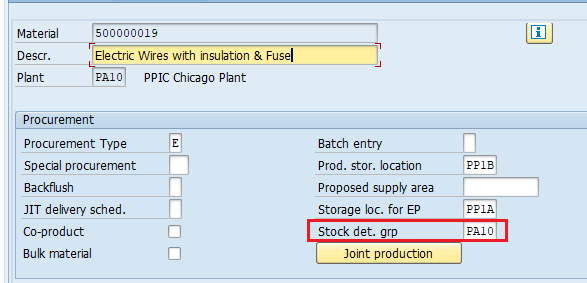

--> Stock Determination Group is assigned to the material master "MRP2" view for the materials which are required to stage from standard location to production location through pull list.

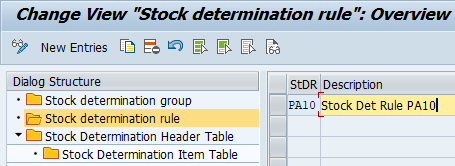

3.4.1.2 Stock Determination Rule

We have configured the stock determination rule as “PA10”

3.4.1.3 Stock Determination Rule Assignment

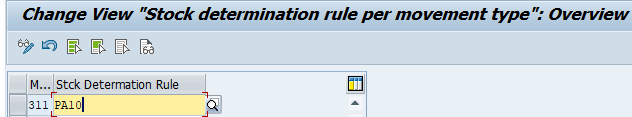

Since staging works with movement type “311” so our stock determination rule needs to be assigned 311 movement type

Follow the below path for this configuration

SPRO –> Material Management –> Inventory Management and Physical Inventory –> Stock Determination –> Assign Stock Determination Rule in the Applications –> Inventory Management

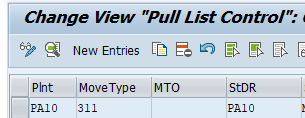

Pull list control is configured as per below path

SPRO –> Production –> Repetitive Manufacturing –> Material Staging –> Define Control Data for Pull List

Here assigned the Stock determination group to our plant

we will now execute the staging through pull list

3.5 Production Order Creation

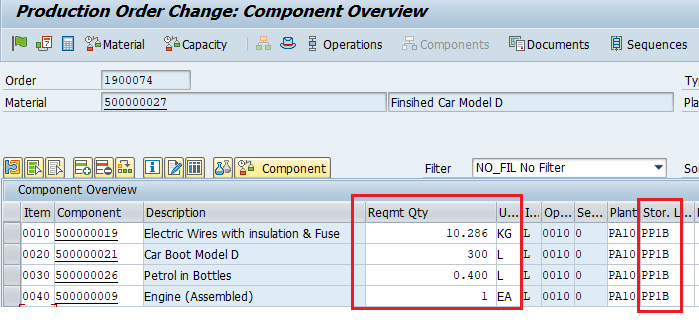

Create the production order for the FG 500000027 (Finished Car Model “D”)

Please see the below post to see how to create production order in detail

How to Configure Base PP Cycle in 5 Minutes

Click on component tab and you can see the component requirement to produce 1 EA of FG, 500000027 (Finished Car Model “D”) as per the BOM. See the highlighted part below

Also note down the production storage location “PP1B” coming from the material master MRP2 view as explained HERE

save and create the Production order 1900074

3.6 Production Order Staging Execution

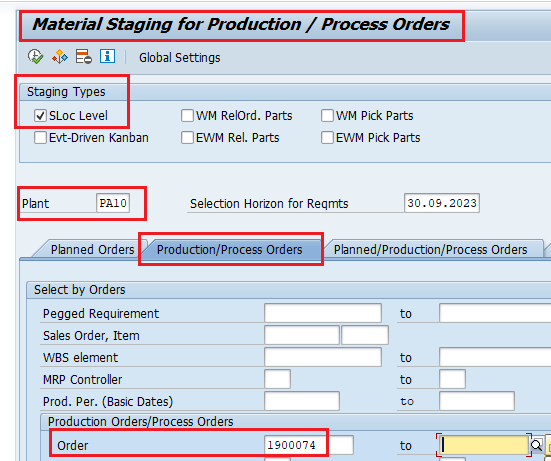

Run MF60

input your plant (PA10) and production order (1900074)

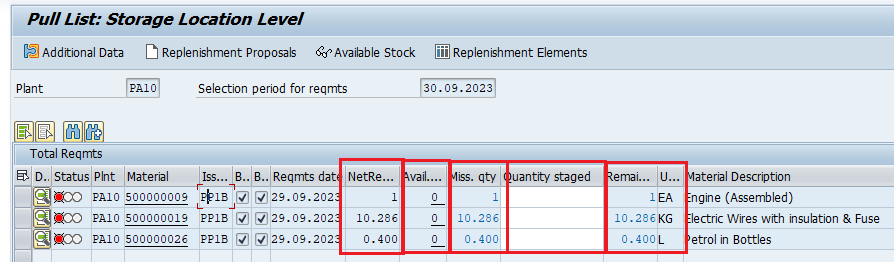

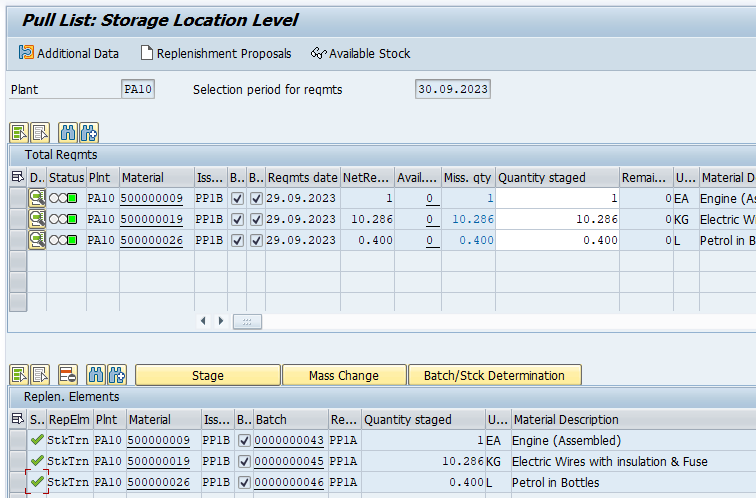

Execute it and the pull list checks the stock situation at the production storage location (PP1B) and calculates the quantities of missing parts and list them as shown below

- “Net” Requirements is the quantity required as per BOM

- Available stock is the qty available at production SLOC (PP1B)

- Missing qty is the Net requirement -Available qty.

- Quantity staged is the qty to be transferred to the production SLOC through this staging

- Remaining qty is the qty left over after this staging

--> Please note that only 3 components have been considered by pull list. The reason is they are available at standard SLOC (PP1A). So they are required to transfer to Production SLOC (PP1B) to execute the production. --> The fourth component i.e. assemble is already available at production SLOC (PP1B) through in house production that's why pull list did not include it in the staging requirement. Please check the stock screenshots HERE

Now we are staging the full qty as the requirement. Input the qty in the “quantity staged” column.

Note that Remaining Mat column is now showing zero qty.

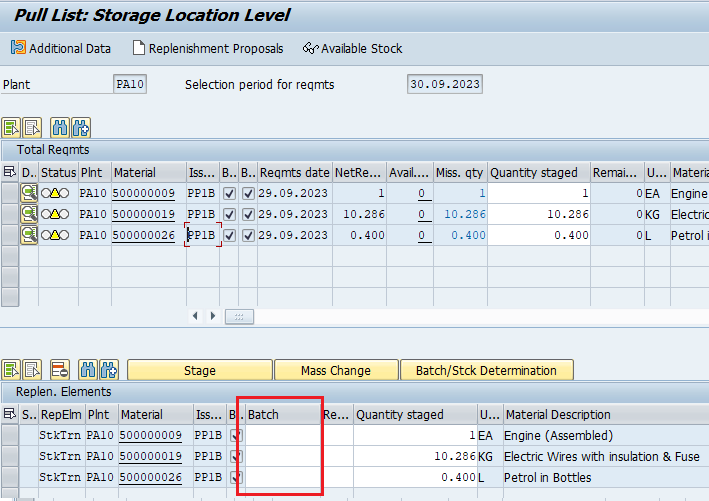

Select all the three rows and click on “Replenishment Elements”

System will present the below screen

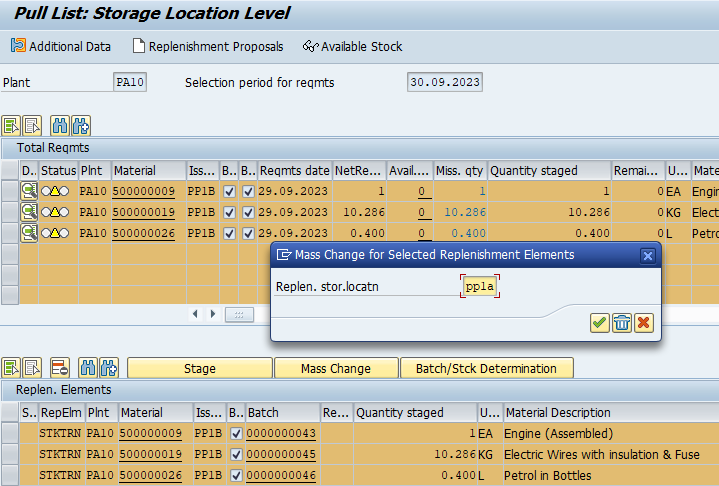

Now input the batch for each component to be staged

Note : To avoid manual batch input, we have configured batch search strategy given in the below post

Once you input the batch click on mass change and input the issuing SLOC

Now select 1 line and click on “Stage”

System has staged the material successfully and created the material document in the background

3.6.1 Production Order Staging Material Document

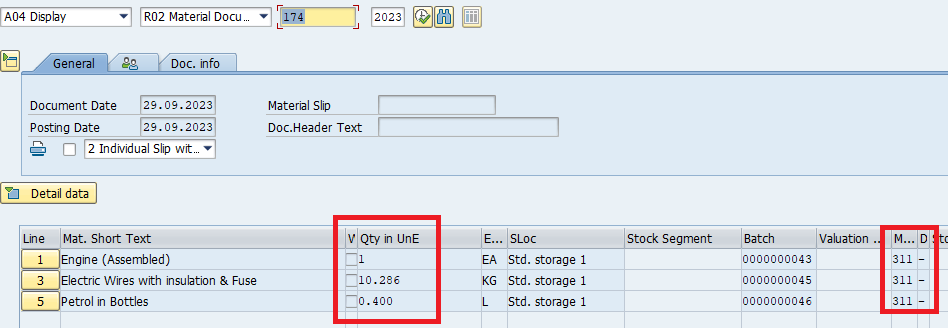

System has created a 311 movement type material document consisting of all the three components staged from main SLOC (PP1A) to the production SLOC (PP1B)

3.6.2 Stock Situation after Staging Execution

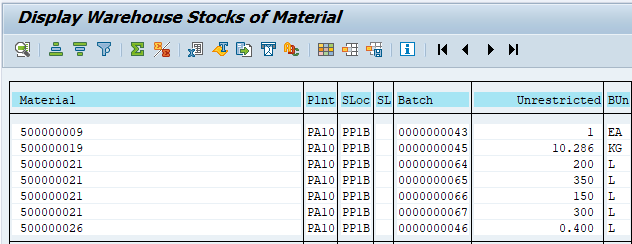

Now check the stock at production SLOC (PP1B). All 4 components should have sufficient stock now to produce the FG

Note: Assembly (500000021) stock was already present at production SLOC (PP1B) due to in-house production. Stock of the rest three components in the above screenshot are maintained through staging

Here production order staging ends.

Image by macrovector on Freepik