SAP Delivery (Outbound to Inbound) is a critical component of the SAP Supply Chain Management (SCM), SAP Materials Management (MM) and SAP Sales and Distribution (SD) modules.

SAP Delivery (Outbound to Inbound) consists the processes involved in

- The shipment of goods from a company’s warehouse or production facility to the customer’s specified location.

- The shipment of the goods from a supplier’s warehouse or production facility to our business specified location.

Here inn this post we will in-depth look at SAP Delivery (Outbound & Inbound)

Table of Contents

1. Deliveries in SAP

If our business is buying & selling then there are business documents like purchase order or sales order to specify what we purchasing or selling, at what price, on which date etc.

Since there are several activities (like picking/put away, packing etc.) between specifying buying or selling details (by Sales Organizations/Purchase Organizations) & actual delivery/supply of goods so there should be a connection between the purchaser order/sales order & actual receipt/delivery of goods. Deliveries fulfils this connection.

Deliveries in SAP specified by its direction . Deliveries related to inbound direction are inbound deliveries. Similarly deliveries related to outbound direction are inbound deliveries

Below are the main type of deliveries used in SAP and their respective preceding documents Sales Order --> Outbound Delivery Purchase Order --> Inbound Delivery Stock Transport Order --> Replenishment Delivery Subcontracting purchase Order --> Subcontracting Delivery

Let’s first have a common configuration to both inbound & outbound deliveries.

1.1 Delivery Type

We will define our delivery types which represent the different business transactions in shipping.

Delivery type configuration determines the below properties

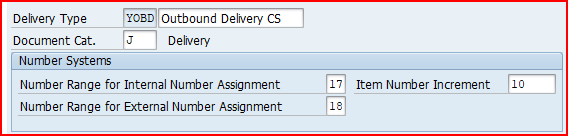

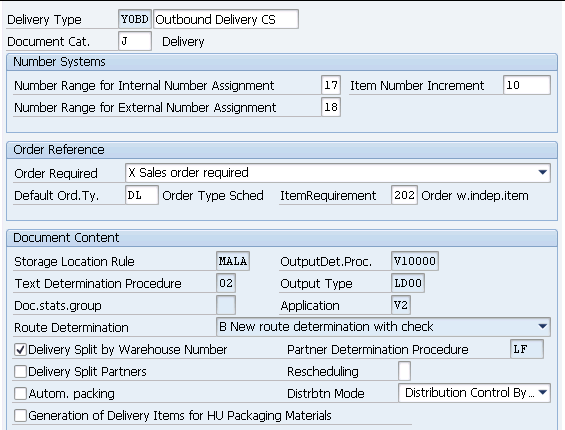

1.1.1 Fields in the Header & Section “Number Systems”

- Document category [J] = Delivery-A classification for the different types of documents in sales and distribution Example : Quotations, Sales orders, Deliveries and Invoices.

- Item number increment: The increment by which item numbers is a sales, delivery or billing document to increase.

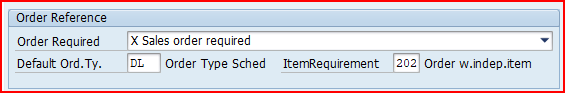

1.1.2 Fields in the “Order Reference” Section

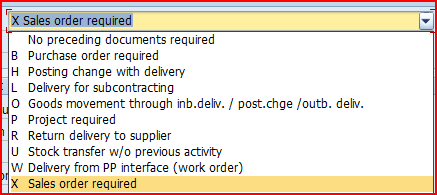

- Order required= Indicates whether a delivery that has no reference to an existing sales order is allowed.

Depending on the business scenario, the other possible value for this fields are

- Default order type [DL] = Default order type for deliveries without reference to order

--> In the order type customizing , we define the delivery process and subsequent billing process that follows. --> But a delivery without any reference to real sales order, we have to define a default order type (DL here) in the Customizing for the delivery type. The Customizing for this default order type (DL) contains the default billing type for billing this delivery.

- Item requirement [202] = Requirement for item that does not refer to a sales order. It identifies a requirements routine for a delivery item that does not refer to a sales document.

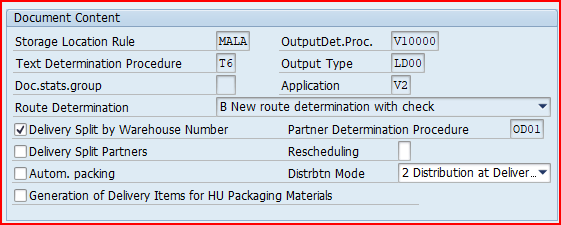

1.1.3 Fields in the “Document Content” Section

- Storage Location Rule: It specifies how the system determines the picking location when delivery is created without entering a storage location for the items.

- Route determination : It specifies whether, during delivery processing, the system uses the route that is determined during sales order or whether it determines a new route.

- Delivery split Warehouse Number: It enables delivery spilt according to warehouse number

- Automatic packing: Automatic packing proposal is retrieved when a delivery is created. All items will be packed.

- General packing material item: This is used to allow generation of delivery items for packaging materials.

- Partner determination procedure : A grouping of partner functions. The procedure specifies which partner functions are allowed for a particular business transaction and which of those partner functions are mandatory.

- Distribution mode : To specify the time at which delivery is distributed to the decentralized WMS.

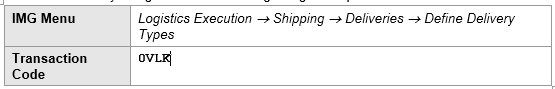

1.2 Delivery Type Configuration

Let’s configure the delivery types for our car business

First we will configure all the outbound delivery type for our car business and then we will configure inbound delivery type.

1.2.1 Outbound Delivery Type Configuration

Outbound deliveries are created against sales order or against stock transport order from the sending plant.

We will configure all the main types of outbound deliveries one by one.

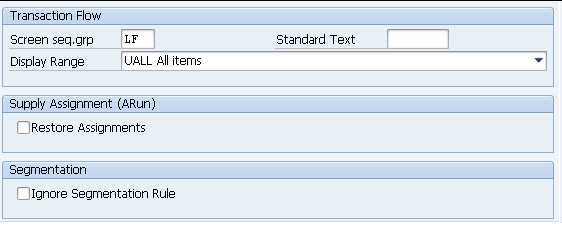

a) YOBD – Standard Outbound Delivery Customer Sales

This delivery will be created based on sales order. We will configure our customized outbound delivery for customer sales

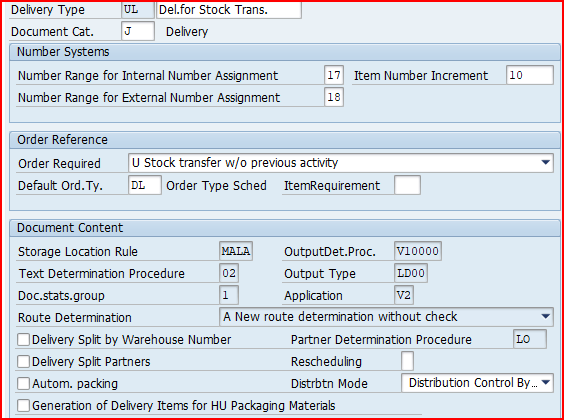

b) UL – Delivery for Stock Transport Order

Here the main difference is the order reference.

For delivery type UL, order reference will be “U-Stock Transfer”

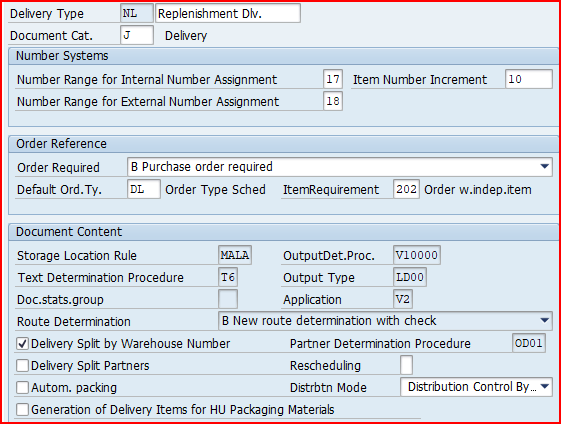

c) NL – Replenishment Delivery

Delivery type “NL” is used for the “Two Step Stock Transfer Order with Delivery”

--> Stock Transport Order (STO) with Delivery is a SAP process to transfer the stock between two plants (or storage locations) within a company

Check the below post for detail

SAP Stock Transport Order with Delivery: A Complete Guide

Here the main difference is the order reference.

For delivery type NL, order reference will be “B-Purchase Order Required”

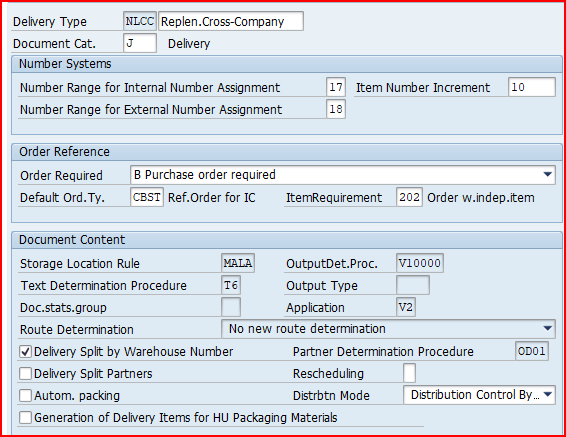

d) NLCC -Replenishment Cross-Company

This delivery type is used in the business process Replenishment Cross-Company

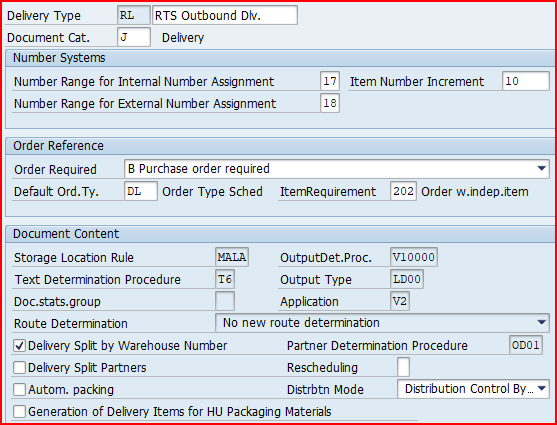

e) RL – Return to Supplier Outbound Delivery

This delivery type will be used for Return to Supplier Outbound Delivery

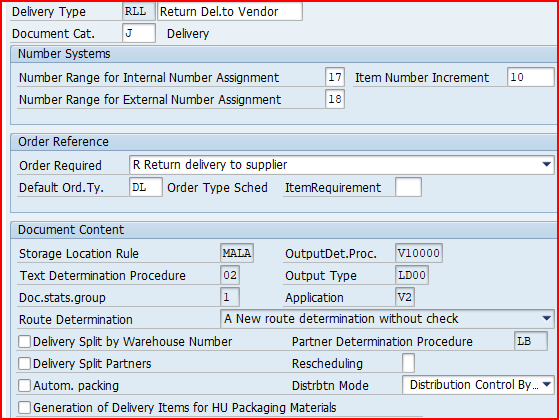

f) RLL – Return Del.to Vendor

Delivery type RLL is configured as per below

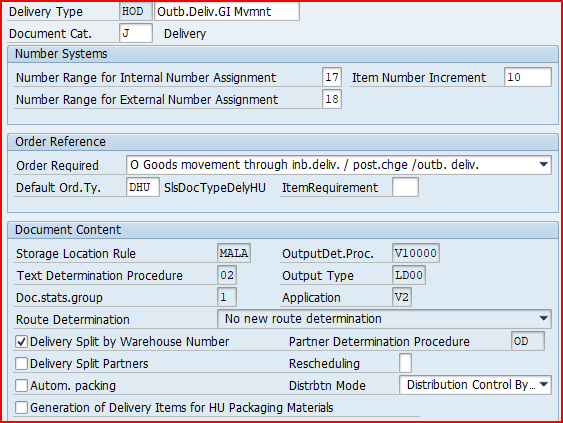

g) HOD – Outb.Deliv.GI Movement

Delivery type HOD is configured as per below

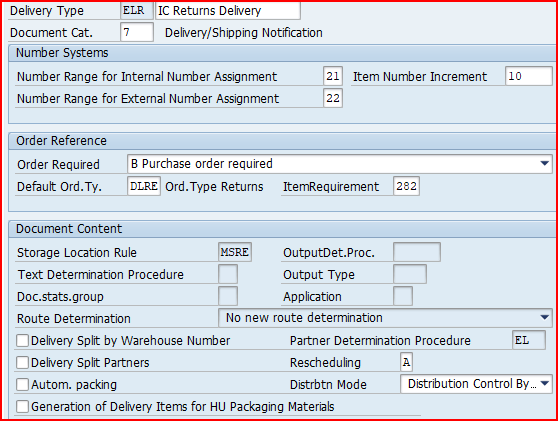

h) ELR-Inter-Company Returns Delivery

Delivery type ELR is configured as per below

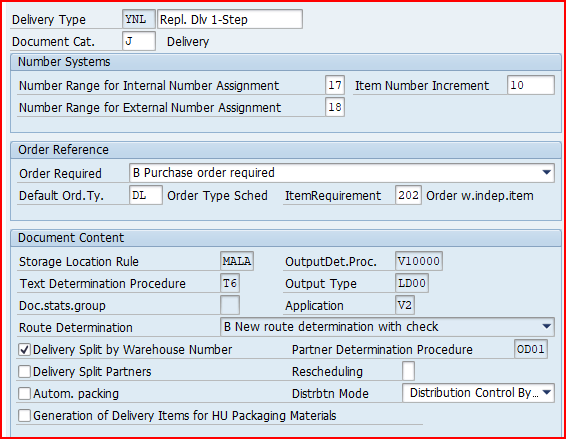

i) YNL-1 Step STO with Delivery

We have configured delivery type “YNL” for 1-Step STO with Delivery

“YNL” is configured as per the screenshot below

1.2.2 Inbound Delivery Type Configuration

As name specifies, inbound deliveries are used for the goods direction inbound to our business.

Inbound deliveries are created based on the purchase orders and then further activities, such as packing, placing in storage, creating the warehouse order, and posting the goods receipt are done on the basis of inbound delivery

Delivery type for the inbound delivery is determined from the confirmation control. Please click HERE to see the details.

In addition to this there must be a default order type defined for the delivery type as we need customizing for order type. But for the deliveries which does not have any link to real sales order a default order type “DL” is defined.

This default order type "DL" uses the copy control “Order Type to Delivery Type” (i.e. from "DL" to "YEL") to transfer information from the purchase order to the delivery using the data transfer routine

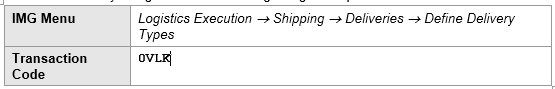

a) YEL-Inbound Delivery for our car business

We will configure our customized inbound delivery type YEL for our car business.

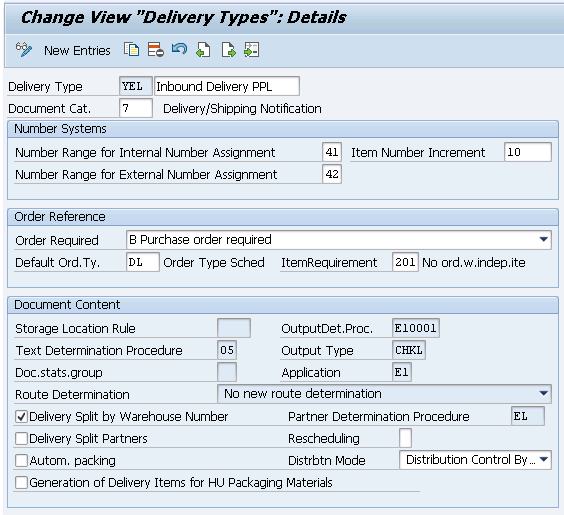

b) HID-Inbound Delivery HU Movement

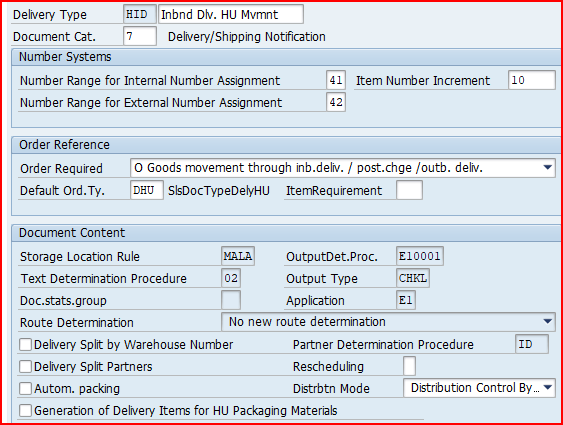

c) LB – Subcon Delivery

1.3 Copy Control

First we will look into copy control for outbound delivery in detail.

1.3.1 Copy Control for Outbound Delivery

Here we will look into the copy control setting for the different business scenarios

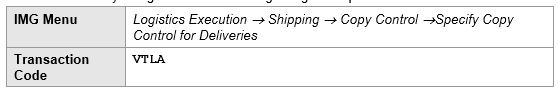

1.3.1.1 Copy Control for Std. Sales order to Std. Delivery

a) Header Data Copy

We will first maintain copy control to copy header data

Please maintain copy control as per the screenshot shown below

b) Item Copy

Now we will maintain copy control to copy Items

Please maintain copy control as per the screenshot shown below

Since for our standard sales order “YOR” & outbound delivery “YOBD”, we have configured a specific item category “YTAN” instead of system standard “TAN” so we need to main copy control to resolve the copy control error shown HERE

Please maintain copy control as per the screenshot shown below

1.3.1.2 Copy Control for Stock Transfer Order with Delivery

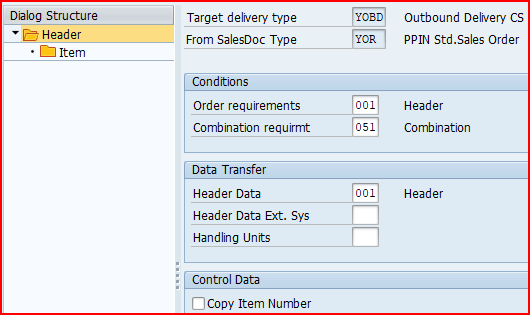

For the SAP Stock Transport Order with Delivery, delivery type is “NL”.

Here if preceding document is Purchasing Order then we use “From Sales DocType” type as “DL”

a) Header Data Copy

We will first maintain copy control to copy header data

Please maintain copy control as per the screenshot shown below

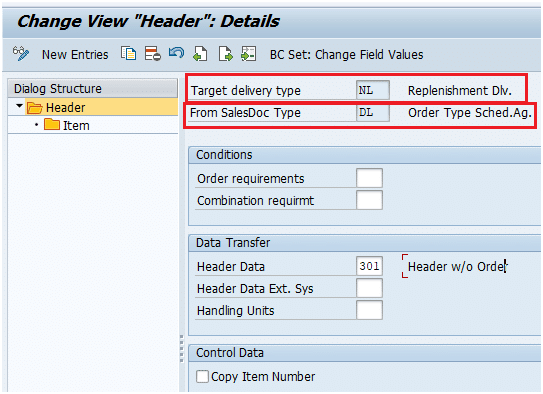

b) Item Data Copy

Since we use Item category as “NLN” for Stock Transfer Order with Delivery , so we will maintain copy control for “NLN” at item category level

1.3.1.3 Copy Control for 1-Step Stock Transfer Order with Delivery

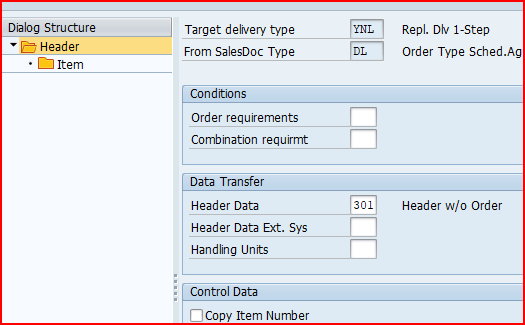

For 1-Step SAP Stock Transport Order with Delivery, delivery type is “YNL”.

Here if preceding document is Purchasing Order then we use “From Sales DocType” type as “DL”

a) Header Data Copy

We will first maintain copy control to copy header data

Please maintain copy control as per the screenshot shown below

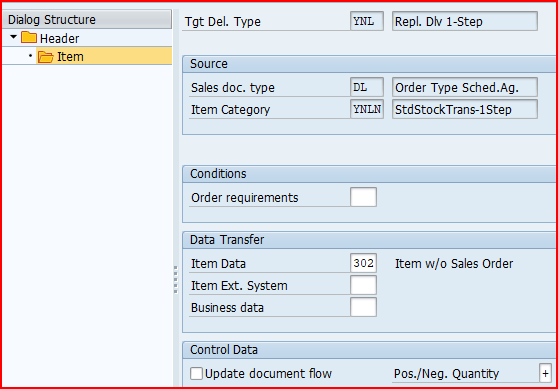

b) Item Data Copy

Since we use Item category as “YNLN” for 1-Step Stock Transfer Order with Delivery , so we will maintain copy control for “YNLN” at item category level

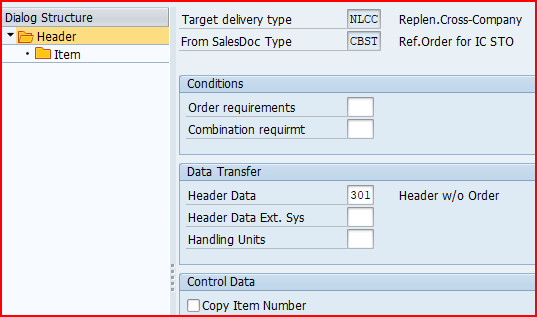

1.3.1.4 Copy Control for Inter-company STO Process with Delivery & Billing

For Inter-company STO Process with Delivery & Billing, delivery type is “NLCC”.

For this process we use reference document type as CBST

a) Header Data Copy

We will first maintain copy control to copy header data

Please maintain copy control as per the screenshot shown below

b) Item Data Copy

Since we use Item category as “NLC” for Inter-company STO Process with Delivery & Billing , we will maintain copy control for “NLC” at item category level

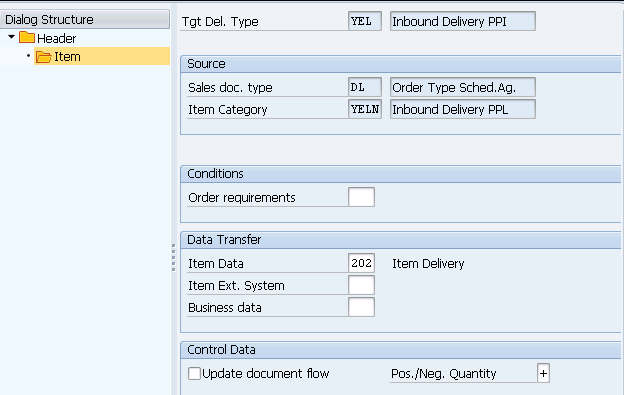

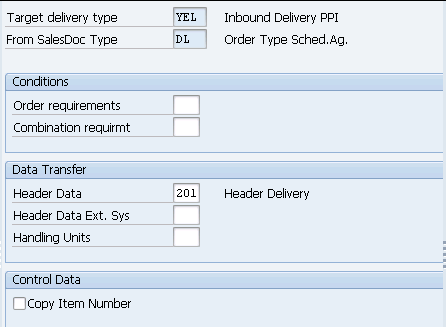

1.3.2 Copy Control for Inbound Delivery

For inbound delivery we need to maintain copy control from default order type “DL” to our delivery type “YEL”

a) Header Data Copy

b) Item Copy