Table of Contents

1. Overview

In SAP, SU (Storage Unit) represents different type of packages like Carton, Pallets etc in Warehouse. Similarly a HU (Handling Unit) too represents different type of package like Carton, Pallets etc. in Supply Chain.

Then what is difference between SU & HU. The difference is in existence

Storage Unit(SU) exists in WM only, while Handling Unit (HU) exists in Global Supply Chain.

2. Configuration Options in SAP for HU vs SU

Storage location is the top most organization structure to manage the stock further in the plants.

There are three Options to manage the stock under a SLOC (Storage Location) --> Stock is managed on SLOC level. --> Stock is managed on SLOC level with handling unit management (HUM). --> Stock is managed further to SLOC on storage bin level with only Storage Unit or Handling Unit as Storage Unit --> To manage the stock in SU, we require Warehouse Management . A warehouse is defined for the plant, SLOC combination. if only SU is used then warehouse and corresponding storage types are required to be defined for SUM

2.1 Storage Locations Scenarios

We have created a total of 14 storage locations for our car business

These 14 storage locations are distributed into the different scenarios as explained below

2.1.1 Scenario 1: Standard Storage Locations

We have created below three standard storage locations for our each plant

- PP1A : Standard Storage location 1

- PP1B : Standard Storage location 2

- PP1C : Raw Material

Please check below post for detail

Configure SAP S4 HANA Material Management Organization Structure in 5 Minutes – Standard Storage Locations

2.1.2 Scenario 2: HU Mandatory IM Storage Locations

These storage locations are standard (IM managed) but HU is mandatory i.e. stock can be managed only in HU in these storage locations.

We have created below SLOCs as HU Mandatory IM Storage Locations

- PP21: IM HU Mandatory SLOC

- PP22: HU managed IM SLOC. (No WM managed)

2.1.3 Scenario 3: EWM Storage Locations

These storage locations are connected to a EWM warehouse.

We have created below three EWM storage locations

- PP1D : EWM Rec. on Dock

- PP1S : EWM Available for Sale

- PPSA : Prod SLOC

Please check below post for detail

Configure SAP S4 HANA Material Management Organization Structure in 5 Minutes – EWM managed Storage Locations

2.1.4 Scenario 4: WM Storage Locations

We have created below two storage locations for Warehouse Management (WM).

- PP20: SLOC with Warehouse Management (WM)

- PP22: SLOC with Warehouse Management (WM) & Handling Unit Management (HUM) mandatory.

Note

- Since WM is now going to be obsolete so we will not configure WM.

- So We will use WM managed storage locations (PP20 & PP22) for other use. For example-we will use PP20 SLOC now as a IM HUM partner SLOC

3. Scenario 1- Standard IM Managed SLOC.

In this option we manage the stock no further than storage location (SLOC) level

3.1 Features of Scenario- 1

Below are the characteristics of scenario 1

- No HU is used.

- Once storage locations are defined then no further configuration is required to manage the inventory.

- Only we need to extend the materials to all the storage locations (on which stock is to be managed).

This is a simple & straight scenario.

--> Please note that we can receive HUs with SSCC number without doing any further configuration of HUs on standard storage location. Only Config required is SSCC generation & packaging material type configuration. --> This happens in the cases where packing happens before delivery takes place. --> But these HUs will not be a part of MM-IV-GF (storage location inventory level)

3.2 Testing of Scenario-1

A Material is created in our plant PA10. Check the below post for the material creation

2 Minutes Guide to Create your First Material in S4 HANA

First we will receive the goods and then dispatch the goods.

a) Receiving the Goods

Purchase Order is created for Material to be procured and Good receipt is done once material is received in the warehouse. Once Good received is done material is available in Storage location of the plant.

Check the below posts for the full process till good receipt on SLOC

All About Purchase Orders in SAP MM

We have created PO & IBD in SAP_

a1) Scenario 1 -Packing

We can pack and create SSCC number if it requires.

Just pack in inbound delivery and post the GR

b) Dispatching the Goods

We have created a sales order and OBD . We can use SSCC number in OBD or we just simply can pick and PGI. System is not going to check any type of SSCC number related checking

We can use Packing and generate SSCC number in option 1 , if we want but system does not execute any type of checking on the SSCC/HU.

c) Production Staging

In it,s simplest explanation, Material staging for production means transferring the materials from the main storage location to the production storage location.

Here we will test staging of production from the main standard IM managed storage location to the standard IM managed production supply location

Please see the below post for detail

Material Staging for Production

4. Scenario 2- IM Managed SLOC with HU Management

In this option stock is managed on storage location level with Handling Unit Management (HUM) activated.

In addition to storage location configuration, HU related configuration also needs to be done. We have the option of generating either an internal HU number or SSCC according to EAN128. All the stock movement/posting changes happens through deliveries.

4.1 Configuration of Scenario 2

Let’s configure the option 2 in the system in details and see the characteristics of this option.

4.1.1 Handling Unit Configuration

Here we will configure HU related settings

Please see the below post to check the HU related configuration in detail

Unlock SAP Efficiency: Master Handling Units Now!

4.1.2 HU Requirement for Storage Location

In this configuration, we will maintain the HU requirement for each storage location and the default values for creating a delivery.

When we set the HU requirement indicator for a storage location, we can only make stock postings if we specify the handling unit

If you do not specify the handling unit, the system does not create a material document when you make the posting but creates a delivery document

SPRO –> Logistics – General –> Handling Unit Management –> Basics –> Materials Management –> Inventory Management –> HU Requirement for Storage Locations and Default Values for Deliveries

First we will define default sales org, Distribution channel & shipping point for the deliveries

then we will define the PP21 & PP22 as a HUM mandatory SLOCs & PP20 as partner SLOC

4.1.2.1 Partner Storage Location

In the above configuration, since the stock in storage location PP21 & PP22 is subjected to a handling unit requirement, so stock is packed in principle, we must maintain a partner storage location for transactions such as unpacking.

We have used Standard SLOC PP20 as a partner location.

4.1.3 Configure default values for creating a delivery

SPRO –> Logistics – General –> Handling Unit Management –> Basics –> Materials Management –> Inventory Management –> Set QM Check and Delivery Type for Each Movement Type

Here we maintain the delivery categories corresponding to every movement type

4.2.3.1 Delivery Categories

Below are the delivery categories defined in SAP

| Delivery Category | Delivery Category Description |

| ID | Delivery Category for Inbound Deliveries |

| OD | Delivery Category for Outbound Deliveries |

| TP | Delivery Category for Stock Transfer Deliveries/Posting Changes |

| RL | Delivery Category for Return Delivery to Supplier |

| LB | Delivery Category for Subcontracting |

| RK | Delivery Category for Customer Returns |

Let’s check/configure for 561 movement type as an example

4.1.4 Delivery Type Determination

Below is the path to configure delivery type determination

SPRO –> Logistics – General –> Handling Unit Management –> Basics –> Delivery –> Delivery Type Determination

a) Delivery type determination for inbound delivery

b) Delivery type determination for Outbound delivery

c) Delivery type determination for Posting Change

4.2 Testing of Scenario 2

We will test the option 2 through two scenarios

4.2.1 Scenario 2.1 (Inbound) : Goods Receipt through initial Upload (Movement Type 561)

Let’s receipt the material through 561 movement type on IM HU SLOC PP21

Start MIGO –> Goods Receipt –> Other

As expected system has created inbound delivery

Check delivery type, system has created inbound delivery with type as “HID” as expected

Now if we try to do the goods receipt of this inbound delivery without creating HU , then system will throw error

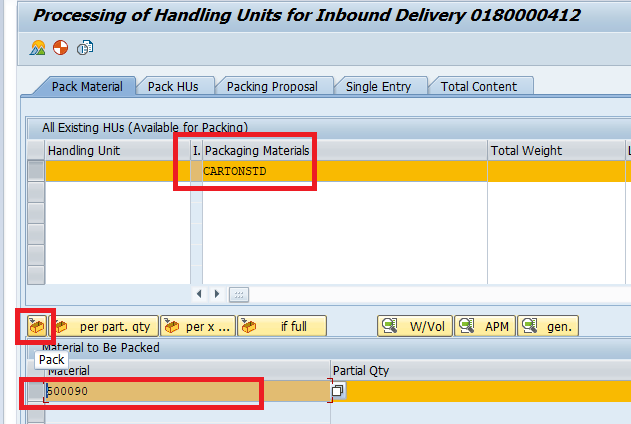

To resolve this error pack in the inbound delivery

Note : HU number should be generated as per SSCC/EAN128 according to the packaging material type “SCAR” assigned to our packaging material “CARTONSTD”

a) Error M7279 – Data for delivery creation is incomplete

To resolve this error We need to assign plant to a vendor.

TIP

input your plant in table T001W and look for plant vendor. if It is available then the above error will not come.

We assign our plant PA10 to the already created vendor PA01VEN01

GR is done successfully now and HU is received in stock

Please see the below post to check the configuration of FI integration of this scenario

Ultimate guide to configure S4 HANA MM-FI Integration – Loading the Stock through MIGO/561

4.2.2 Scenario 2.2 (Inbound) : Material Receipt through External Vendor

in this scenario we will create a PO and then IBD based on the PO.

We want to manage stock on IM storage location but in HU. To create the HU we need to pack in Inbound delivery while receiving the stock.

Crete a PO and Inbound delivery to receive the stock on PA21 SLOC

Inbound Delivery Created to receive the stock on IM HU PP21 SLOC

Check the below posts for the full process till good receipt on SLOC

All About Purchase Orders in SAP MM

GR is done and HU is now present in the plant on PP21 SLOC

4.2.3 Scenario 2.3: HU Movement between HU Managed & Non-HU Managed SLOCs

To move the HU among the HU managed and non-HU managed SLOCs we use VLMOVE & HUMO

a) VLMOVE

To move the full HU between HU-managed storage locations and non-HU storage locations we can use VLMOVE

b) HUMO

To move the full HU between HU-managed storage locations and non-HU storage locations we can use HUMO

c) Control of Movements used in VLMOVE & HUMO

In the below configuration, we define the movement types that are used for HU-specific material postings. The Packing process defines the movement type with which the packed (or unpacked) material is transferred between HU-managed storage locations and non-HU storage locations through the posting process in the Handling Unit Monitor (HUMO) and in the Goods Movements for Handling Units and Materials (VLMOVE) transaction.

SPRO –> Logistics – General –> Handling Unit Management –> Basics –> Technical Basics –> Maintain Goods Movements for Handling Unit Stock-Posting

4.2.4 Scenario 2.4 (Outbound) : Picking the HU for the OBD with Goods issue

In this scenario we will test a end to end outbound cycle.

Created a sales order and OBD. In the OBD input picking qty & batch and click on Pack

Please note that sales order & OBD is for 1 EA and HU we will try to pick is of 7 EA.

Input the HU to be picked and click on Pack as shown below

Unpack the material through HU02 to PP1B SLOC . Then again packed the material in 1 qty to PP21 SLOC

Now go to packing dialogues of VL02N and try to pick this newly packed 1 EA HU 86543210300000448

HU is picked now

HU is picked now. Execute the Post goods issue of outbound delivery.

Please see the below post for PGI related errors (SD-FI integration) & resolution

SAP SD FI Integration and Account Determination

Execute the Post goods issue of outbound delivery

PGI is done. Material & Accounting Document is generated

Check Accounting Document

5. Scenario 3 -EWM Managed SLOC

SAP Extended Warehouse Management (SAP EWM) is a WMS module from the SAP Supply Chain Management (SAP SCM) solution package.

EWM is a very flexible warehouse management system which is designed to manage high-volume warehouse operations.

EWM provides flexible, automated & advanced features to manage the stock movements of the entire warehouse process, from goods to picking, packing and removal.

We have created below SLOC to be EWM managed

- PP1D : EWM Rec. on Dock

- PP1S : EWM Available for Sale

- PPSA : Prod SLOC

Please see the below post to check the EWM configuration in detail

6. Scenario 4 -WM Managed SLOC

In this option stock is managed further to SLOC level up-to the warehouse bin level. Storage location is assigned to plant & warehouse.

in option 3, there are further two options to manage the stock

- Stock is managed in Storage Units (SU). SUs are valid only inside the warehouse

- Stock is managed in Handling Units . HUs are valid inside as well as outside the warehouse.

We will not explore this scenario further as SAP WM is retiring now. SAP EWM is the preferred WMS from SAP now

6.1 Scenario 4.1 – Stock is managed in Storage Units (SU)

in this option, stock is managed in SUs inside the warehouse. You need to declare warehouse and required storage types as SU managed in configuration. A SU is created through an internal SU number range. SU exists only inside the warehouse and lost as soon as material is out from the warehouse.

--> We will not explore/Configure SAP WM scenario further as SAP WM is retiring now. SAP EWM is the preferred WMS from SAP now

6.2 Scenario 4.2 – Stock is managed in Handling Units (HU)

A Handling Unit (HU) becomes Storage Unit (SU) in warehouse with same or different number.

In this option, We manage the stock in HUs. A handling unit is nothing but a packing material and material to be packed combined. We can configure internal HU numbers or a SSCC (Serialized Shipping Container Code) according to EAN128.

You can learn everything about SAP HU and Barcode here

7. Conclusion

As we have seen we can manage the stock in only on IM level, IM with HU level, EWM level & WM level

With the retirement of SAP WM, Stornge Unit Management (SUT) is not a viable option now.

Image by user15245033 on Freepik