Stock Transport Orders (STO) are essential for efficiently managing the movement of materials between different company locations. There are some business cases where you may need to handle stock transfers without creating a delivery.

--> Stock transfer without delivery in SAP is used in various business scenarios where the transfer of goods between locations does not require a shipping document or delivery, but is still necessary for inventory management purposes or to account for delivery cost like freight.

--> A stock transport order without delivery is possible Only in Two-Steps procedure.

Stock Transport Order Without Delivery process not only saves time but also simplifies internal stock management.

In this step-by-step guide, we’ll walk you through the various scenarios of intra-company Stock Transport Order without delivery process.

Table of Contents

1. What is Intra-Company Stock Transport Order Without Delivery

Below is the business scenario & characteristics of Intra-Company Stock Transport Order (STO) without delivery.

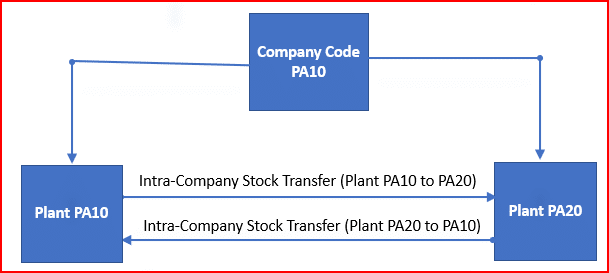

1.1 Stock Transfer Between Plants of the Same Company

As the name specifies, in the Stock Transfer between plants of same company, a company has multiple plants within the same company code and needs to move stock from one plant to another without creating outbound and inbound deliveries.

--> Stock Transfer Between Plants of the same Company code is called Intra company Stock Transfer. The purchase order created for this scenario is called "Intra-Company stock Transport Order"

our car business has two company codes PA10 & PP10

- Company Code PA10 has two plants PA10 & PA20

- Company code PP10 has one plant PP10

The STO between plants PA10 & PA20 (Both belongs to Company Code PA10) will be a intra-company STO).

2. Characteristics of Intra-Company Stock Transport Order Without Delivery

Below are the main Characteristics of Stock Transport Order (STO) Without Delivery

- Only Two step procedure can be executed with stock transport order without delivery.

- We can enter delivery costs in the stock transport order.

- The accounting document in the process is valuated at the valuation price of the material in the issuing plant.

- As soon as quantity is issued from the issuing plant, it is managed as stock in transit of the receiving plant.

3. Configuration of Intra-Company Stock Transport Order Without Delivery

We will configure Intra-Company Stock Transport Order Without Delivery step by step

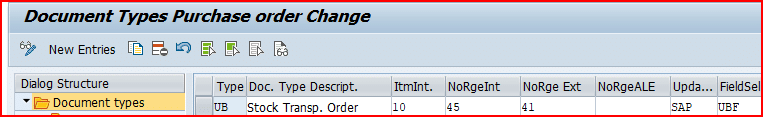

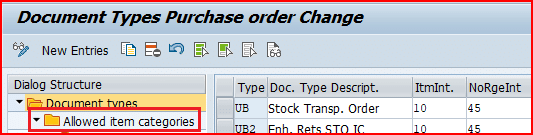

3.1 Configure Document Types

In this configuration, we Check and copy existing document types for purchase orders and define allowed item categories for each document type

Document types configuration controls several factors like define item interval, determine allowed follow-on document types, assign document types to a number range group & number range interval

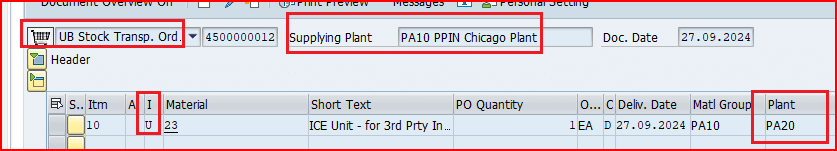

--> For our car business, we will use standard document type "UB" for the Stock Transport Order Without Delivery

Follow the below path for document type configuration

SPRO –> Materials Management –> Purchasing –> Purchase Order –> Define Document Types for Purchase Orders

Select “UB” and click on “Allowed Item Categories”

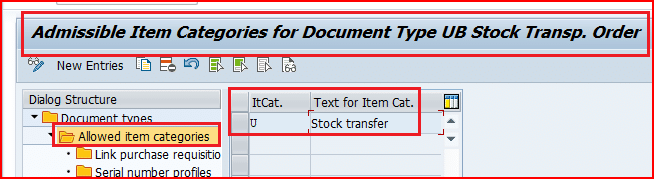

3.2 Item Category

Item category defines how the procurement of a material or service item is controlled.

For the document type “UB” item category U is used

Note : Item Categories can not be configured. These are maintained by SAP, therefore we cannot change them. However, we can change the “External Representation” of PO item categories in IMG.

3.3 Configure Pricing Schema for STO Without Delivery

Please check the below post to Configure Pricing Schema for STO Without Delivery

Ultimate guide to SAP S4 HANA MM Pricing Procedure – Pricing Schema for Stock Transport Orders

4. Testing of Intra-Company Stock Transport Order Without Delivery

We will test below scenarios related to the Intra-Company Stock Transport Order Without Delivery

- Scenario 1: Intra-company Stock Transport Order Without Delivery & without delivery cost

- Scenario 2: Intra-company Stock Transport Order Without Delivery & with delivery cost

- Scenario 3: Intra-company Stock Transport Order With Goods Receipt in Quality Inspection

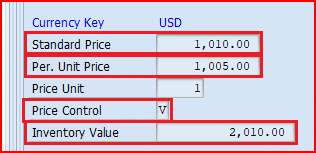

Material prices for all the scenarios

Material price in PA10 plant is 1000 USD at Moving Average Price

Material price in PA20 plant is 1010 USD at Moving Average Price

4.1 Scenario 1: Intra-company STO without Delivery & without Delivery Cost

This is the normal standard straight scenario related to the stock transfer without delivery

To test the STO without delivery, create a STO

4.1.1 Create a Stock Transport Order

Start ME21N and select Document type as UB

Select sending plant as “PA10”

Select receiving plant as “PA20”

Choosing the document type as “UB” will set item category to “U” Automatically

4.1.2 Post the goods issue in the issuing plant

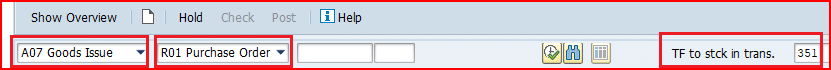

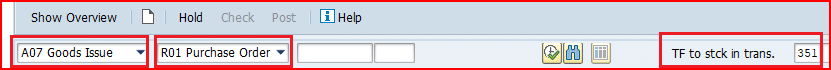

To post the goods issue , start MIGO

Select

A07 -Goods Issue & R01 Purchase Order

System will automatically select 351 movement type

System will fetch all the details from the purchase order

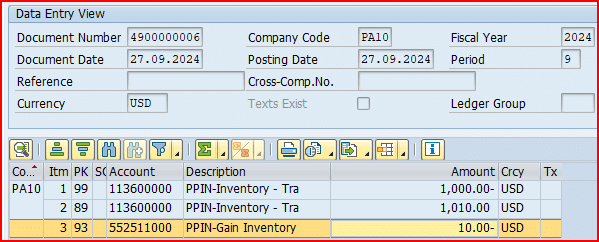

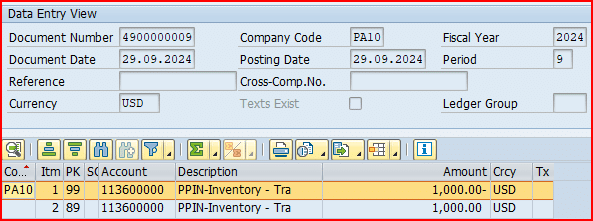

4.1.2.1 Accounting Document at PGI

In our scenario , the material is valuated at 1000 USD in issuing plant & 1010 USD in receiving plant

a) Material Price control is “Standard Price”

If material subjected to stock transfer is valuated at standard price then it’s price remains unchanged in the transaction

since transaction is valuated with issuing plant valuation, so there is a gain of 10 USD in this transaction.

b) Material Price control is “Moving Average Price”

If material, subjected to stock transfer is valuated at moving average price then it’s price changes as a result of the transaction.

since transaction is valuated with issuing plant valuation, and there is no inventory in receiving plant till yet, so after the transaction we will have 1 quantity of this material valuated at 1000 USD

As a result accounting document will be posted 1000 USD credit to inventory account and 1000 USD debit to inventory account

--> Please note that in the case of moving average price control of the material (V) , since there was not inventory in the receiving plant for this material before this transaction, material price updated with the valuation of the sending plant.

--> If there is inventory present before the transaction, then the material price would have been updated with average of the two. For example - in the receiving plant there is already 1 PC at 1010 USD , and 1 PC we receive through this transaction at 1000 USD (sending plant valuation) , then the resulting price of this material would have been 1005 USD for this material in the receiving plant.

c) Automatic GL Posting configuration

here configuration to post to GL is same as 2 step stock transfer as explained in the below post.

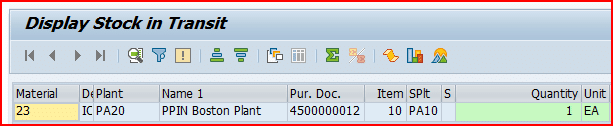

4.1.3 Stock in Transit

One of the main Characteristics of Stock Transport Order Without Delivery is – As soon as quantity is issued from the issuing plant, it is managed as stock in transit of the receiving plant.

To check stock in transit, start MB5T and input receiving plant

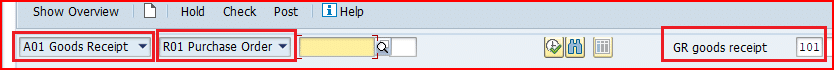

4.1.4 Goods Receipt in the Receiving Plant

To do the Goods receipt in the receiving plant start MIGO

Select “A01 Goods Receipt” & R01 “Purchase Order” , system will automatically select the movement Type as 101

System will fetch all the details, Click the item OK and post the goods reciept

No accounting document is posted in goods receipt

Stock is updated in the receiving plant as well as PO history is updated.

4.2 Scenario 2: Intra-company STO without Delivery & with Delivery Cost

In this scenario we will apply the delivery cost . Let’s assume that we need to pay USD 10 in transportation to deliver 1 EA of material from plant PA10 to plant PA20 ,

We will capture this cost in stock transport order

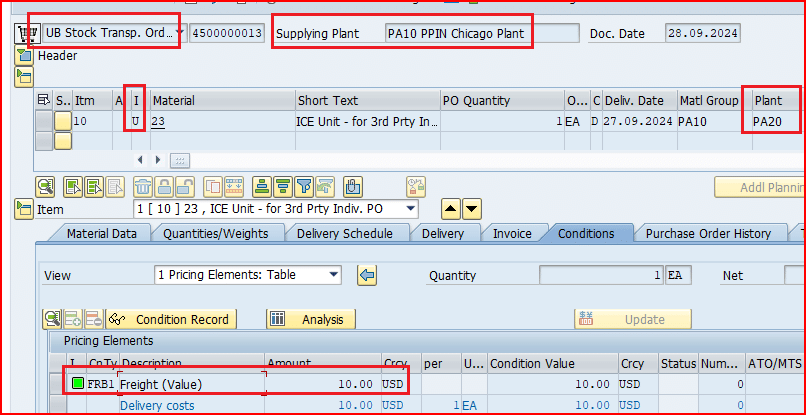

4.1.1 Create a Stock Transport Order

Start ME21N and select Document type as UB

Select sending plant as “PA10”

Select receiving plant as “PA20”

Choosing the document type as “UB” will set item category to “U” Automatically.

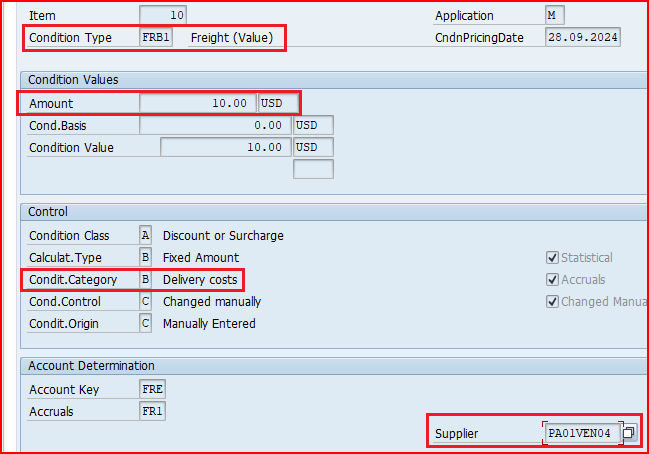

go to the “Condition” tab and select condition FRB1-Freight (Value) and give this condition value as 10 USD

Select the FRB1 line and click on “Condition Detail”

Enter the supplier number providing the transportation services.

4.2.2 Post the goods issue

To post the goods issue , start MIGO

Select

A07 -Goods Issue & R01 Purchase Order

System will automatically select 351 movement type

System will fetch all the details from the purchase order

4.2.2.1 Accounting Document at PGI

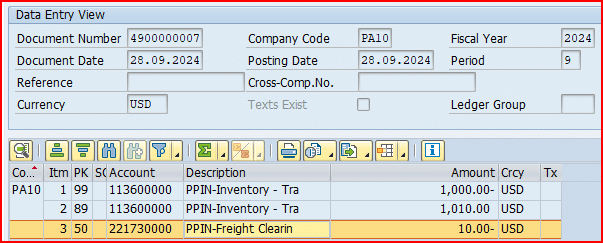

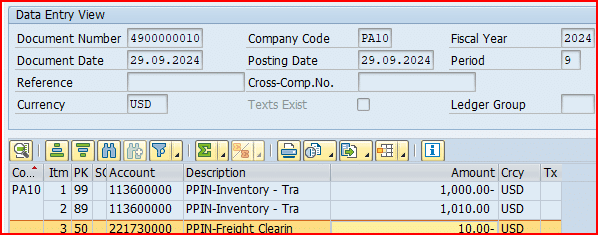

In our scenario , the material is valuated at 1000 USD in issuing plant & 1010 USD in receiving plant

a) Material Price control is “Standard Price”

If material subjected to stock transfer is valuated at standard price then it’s price remains unchanged in the transaction

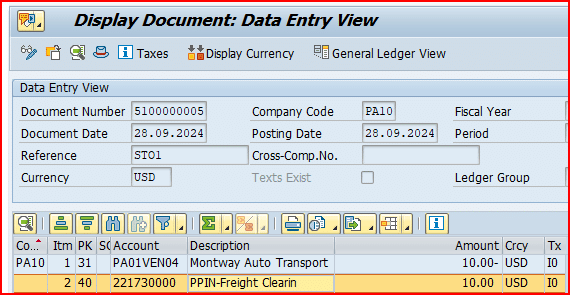

system will post delivery charges to the Freight clearing account.

This freight clearing account is cleared at the time of posting the invoice received from the transportation supplier

b) Material Price control is “Moving Average Price”

If material, subjected to stock transfer is valuated at moving average price then it’s price changes as a result of the transaction.

Valuation of the material in Supplying Plant Plant PA10 – 1000 USD

Valuation of the material in Receiving Plant Plant PA20 – 1000 USD

Delivery charge – 10 USD

Create the PO and input the delivery cost along with supplier number as explained HERE

System will post the below accounting document at the time of post goods issue

--> In the above scenario, material cost in the plant PA20 is updated to 1010 USD due to loading of freight charges of 10 USD on inventory. Since there was already 1 EA was present with price as 1000 USD, so system updated the material price in PA20 plant with the average of the two i.e. 1005 USD (1000+1010)/2

c) Automatic GL Posting configuration

here configuration to post to GL is same as 2 step stock transfer as explained in the below post.

4.2.3 Stock in Transit

It will be same as in the above scenario as explained HERE

4.2.4 Goods Receipt in the Receiving Plant

It will be same as in the above scenario as explained HERE

No accounting document is posted in goods receipt

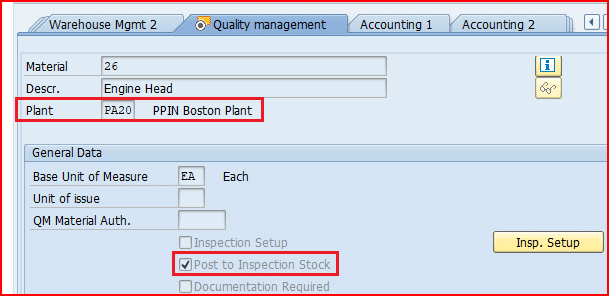

4.3 Scenario 3: Intra-company STO With Goods Receipt in Quality Inspection

The Intra-company Stock Transport Order (STO) with Goods Receipt in Quality Inspection used when transferring materials between plants within the same company, ensuring that goods undergo quality inspection before they can be used in production or sales.

4.3.1 Requirement for Goods Receipt in Quality Inspection

To receipt the goods in quality inspection (QI) in receiving plant, We need to check the indicator “Post to Inspection Stock” in QM view of the material master for the receiving plant.

--> The field "Post to Inspection Stock" Specifies if the material is subject to quality inspection (without inspection lot processing) and whether a goods receipt is posted to inspection stock.

--> This indicator is copied to purchase order items and goods receipt items.

--> If we select this indicator, then no stock-relevant inspection lots can be created.

--> If we activate a stock-relevant inspection type, this field is deselected and can no longer be maintained.

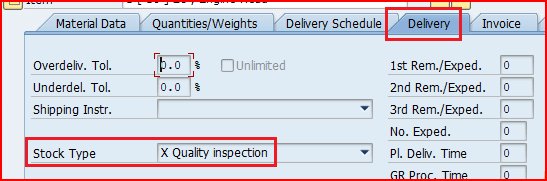

a) Quality Inspection Indicator in Purchase Order

As stated above, if this indicator is selected in material master, then this flows into the purchase order “Delivery” tab.

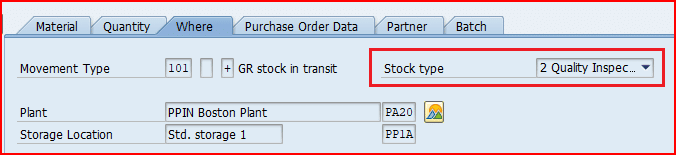

b) Quality Inspection Indicator in Goods Receipt

As stated above, if this indicator is selected in material master, then this flows into the Goods reciept.

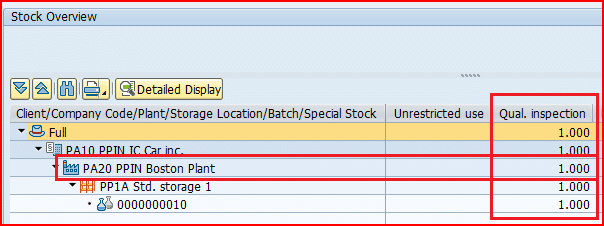

c) QI Stock in Receiving Plant

Now we can see that after GR QI stock is generated in receiving plant for this process.

This completes all the scenarios of Intra-Company Stock Transport Order Without Delivery

Image Courtesy: www.freepik.com