Handling unit is a combination of packaging material & material to be packed. HU concepts make SAP efficient.

We will see in this post how HU unlocks SAP efficiency & we will master Handing unit configuration & usage in this process.

Table of Contents

1. Handling Units (HUs) – Definition & Concept

Below are the main points related to the definition & concept of handling units in SAP

- A handling unit is always a combination of product & packaging materials.

- Handling unit can be nested i.e. new HUs can be created from the other handing units

- HUs are identified through labels in the warehouse. There are two types of HU labels

- Internal HU label – if a HU remains within organization. so if we transfer a HU within a group company company codes or plants , label remains valid without relabeling.

- if goods are transacted external parties like vendor, customer then relabeling is required as internal labels can not be used.

1.1 Packaging Material Type

Packaging Material Type combines similar packaging materials into groups and contains essential control features

We will configure below packaging material type for our Car business.

1.1.1 Packaging Material Type generating SSCC number

- Packaging Material Type “BAGS” (BAGS)

- Packaging Material Type “BOTL” (BOTTLES)

- Packaging Material Type “BOX” (BOX)

- Packaging Material Type “DRUM” (DRUMS)

- Packaging Material Type “MDLD (Finished Car Packaging

- Packaging Material Type “SPPL” (Pallets supplied by Vendors)

- Packaging Material Type “SCAR” (Standard SSCC Carton)

- Packaging Material Type “SPAL” (Standard SSCC Pallet)

1.1.1.1 Configuration of Packaging Material Type generating SSCC number

We will configure the packaging material types which will create a SSCC number

Below is the path

SPRO –> Logistics – General –> Handling Unit Management –> Basics –> Define Packaging Material Types

Let’s configure all such packaging material type one by one.

1. SCAR -SSCC Carton Standard

2) SPAL – SSCC Pallet Standard

Similarly Configure rest of the packaging material types generating SSCC number as shown above.

1.1.2 Packaging Material Type generating “Means of Transports”

Groups of vehicle resources are called “Means of transport”. Some example are -container ships or cargo ships.

Means of transport is assigned to to each vehicle resource. Means of Transport is owned by shipper.

Below are the packaging material type which will generate means of transports

- Packaging Material Type TRUK – Will generate Means of Transport

- Packaging Material Type SEAC – Will generate Means of Transport

- Packaging Material Type AIRC – Will generate Means of Transport

1.1.2.1 Packaging Material Type Configuration generating Means of Transports

Here we will configure the packaging material types which will generate a means of transports.

Below is the path

SPRO –> Logistics – General –> Handling Unit Management –> Basics –> Define Packaging Material Types

Let’s configure all such packaging material type one by one.

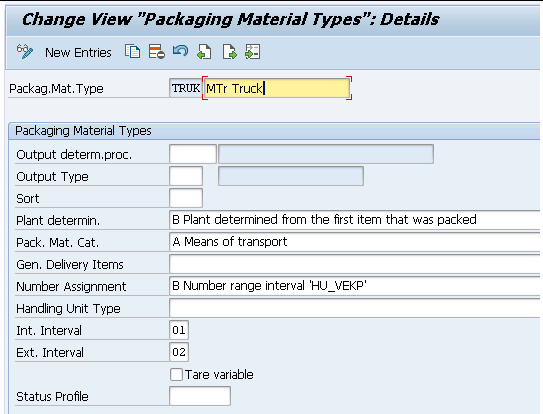

1) TRUK – Means of Transport “Truck”

Means of Transport “TRUK” is configured as per below

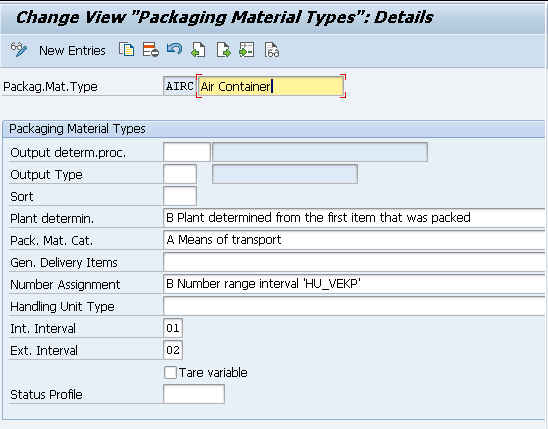

2) AIRC – Means of Transport “Air Container”

Means of Transport “AIRC” is configured as per below

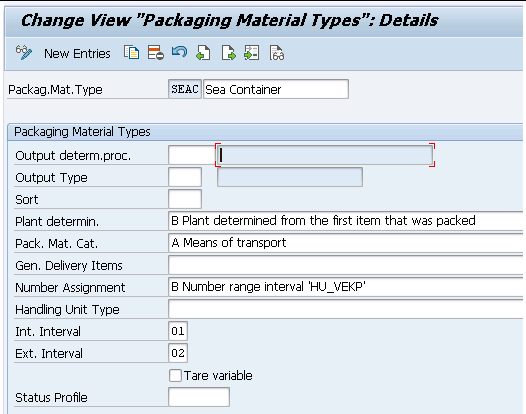

3) SEAC – Means of Transport “Sea Container”

1.1.3 Packaging Material Type generating “Auxiliary packaging Materials”

Auxiliary packaging are supporting packaging materials for generating HU structures like : lids, foil, lining, or trays

Below are the packaging material types which will generate “Auxiliary Materials”

- Packaging Material Type THMM

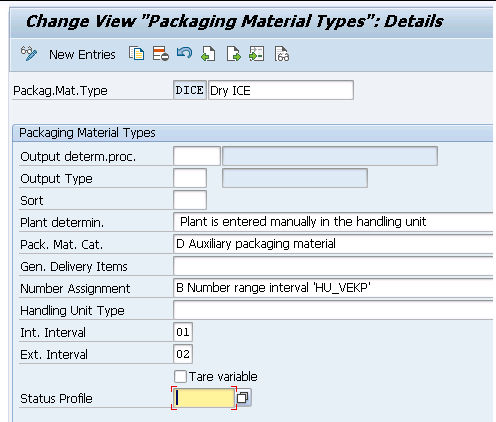

- Packaging Material Type DICE

1.1.3.1 Packaging Material Type Configuration generating “Auxiliary Materials”

Here we will configure the packaging material types which will generate Auxiliary Materials.

Below is the path

SPRO –> Logistics – General –> Handling Unit Management –> Basics –> Define Packaging Material Types

Let’s configure all such packaging material type one by one.

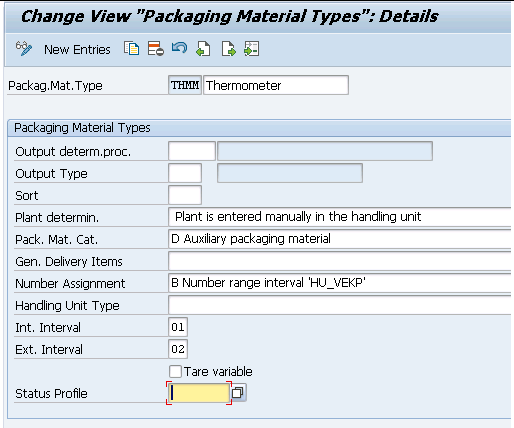

1) THMM – Auxiliary Packaging Material “Thermometer”

2) DICE – Auxiliary Packaging Material “ICE”

1.2 HU Type for EAN128 (Application Identifier 01)

Packaging material type configuration within the EAN128-/UCC128 norms, the shipping unit number/ Serialized Shipping Container Code (SSCC) is used to provide handling units with unique identification. The SSCC is 18 digits long and the first digit specifies the type of handling unit. Carton is represented by “0” & Pallet is represented by “1”

Please check the EAN128 configuration in details through the below link

All About Handling Units and Bar Codes in SAP S4 HANA

1.3 Material Group Packaging Material

Materials that are to be packed into similar packaging materials are grouped together. The material grouping for packaging materials is entered in the material master record of the shipping material.

SPRO –> Logistics – General –> Handling Unit Management –> Basics –> Define Material Group for Packaging Materials

Created Material Group for packaging materials as PKGR

1.4 Allowed Packaging Material

By assigning packaging material types to the material groups for packaging materials, you define which packaging materials are allowed for packing.

Assigned our both packaging material types SCAR & SPAL to our Material group PKGR

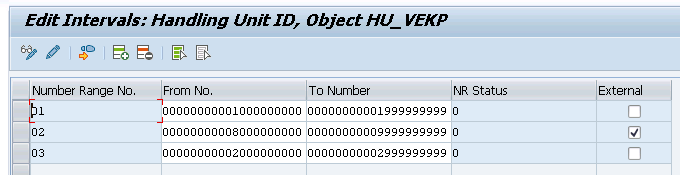

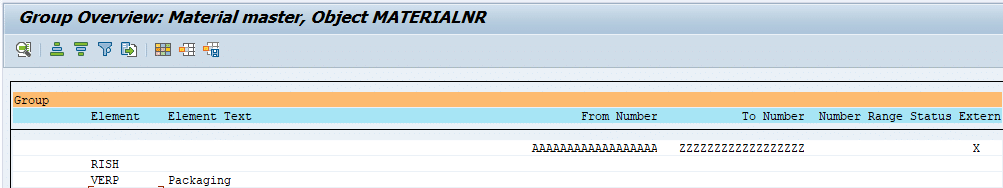

2. Number Range for HU Identification (HU_VEKP)

We can maintain an internal number range or an external number range for HU identification.

--> Note: We can maintain multiple internal and external number range intervals so that various packaging material types create different numbers.

Below is the path for creating number range

SPRO –> Logistics – General –> Handling Unit Management –> External Identification–> Number Range Maintenance for HU Identification

We have maintained the below number ranges

3. Configuration of SSCC Generation Acc. to EAN128

here we will do the configuration to generate Serialized Shipping Container Codes (SSCC).

Note

if we will try to pack in the absence of SSCC number generation while packaging material type configuration mandates it then system will throw the ERROR LE_SHP_BF_EAN128022

This error is due to unavailability of configuration of SSCC Generation Acc. to EAN128

To configure the SSCC generation please follow the below

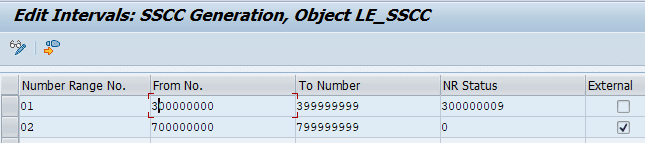

3.1 Maintain Number Range Objects and Intervals for SSCC

We need one object and one internal interval to create sequential SSCCs for entire organization.

We will use Number range object “LE_SSCC” is provided with interval “01”

SPRO –> Logistics – General –> Handling Unit Management –> External Identification –> SSCC Generation Acc. to EAN128 –> Maintain Number Range Objects and Intervals for SSCC

3.2 Maintain SSCC Generation for Plant / Storage Location

Here we configure all the parameters for generating Numbers of Serialized Shipping Container Codes (SSCCs)

Follow the below path

SPRO –> Logistics – General –> Handling Unit Management –> External Identification –> SSCC Generation Acc. to EAN128 –> Maintain SSCC Generation for Each Plant / Storage Location

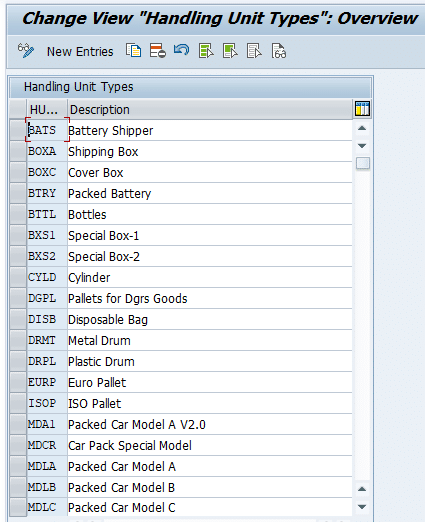

4. HU Type

Here we define handling unit types (HU types). We need HU types in Extended Warehouse Management (EWM) to classify packaging materials and HUs with the same physical properties.

Follow the below path to create HU types in ERP/S4/ECC

SPRO –> Integration with Other SAP Components –> Extended Warehouse Management –> Additional Material Attributes –> Attribute Values for Additional Material Master Fields –> Define Handling Unit Type

We have configured the below HU Types

--> HU Type plays a critical role in EWM. We will see this in the EWM section. --> IN S4 we have created S4 to input the same in material master.

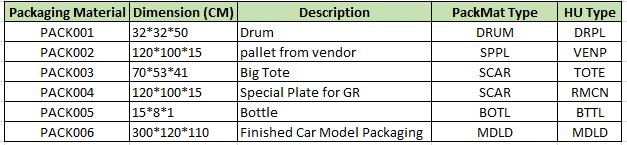

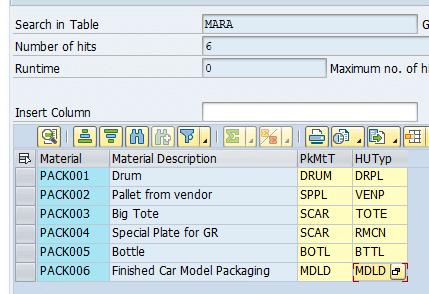

5. Create the Packaging Materials

Now we will create the packaging materials, which are mandatory to work with HUs

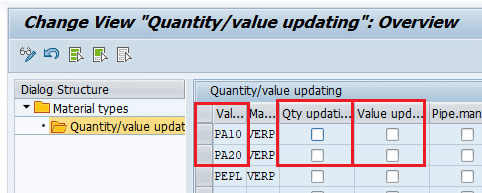

We will use SAP standard material type “VERP” for packaging material

Material type “VERP” has external number ranges

This material type “VERP” is not managed quantity wise or “Value wise” in our valuation areas i.e. our plants PA10, PA20 & PP10

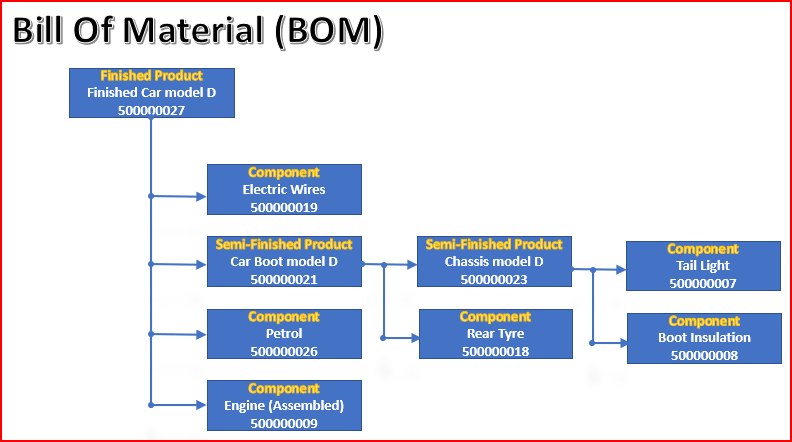

We have the below Bill of Materials

5.1 Packing Arrangement of Materials

Below will be the packaging arrangement of our BOM materials

5.1.1 Assembly (BOM-1)-Chassis Model D (Material no.-500000023)

Components of this BOM will be packed as per below

- Assembly (Semi Finished)-Chassis Model D (Material no.-500000023) will be received from the production into Packaging Big Tote “PACK003” in 1 each.

- Component-Tail Lights (Material no.-500000007) will be packed into Packaging material Plastic Drum “PACK001” in 10 KG each and 18 such drums are packed on Pallet “PACK002” supplied by vendor

- Component-Boot Insulation (Material no.-500000008) will be packed into Packaging material Plastic Drum “PACK001” in 10 KG each and 18 such drums are packed on Pallet “PACK002” supplied by vendor

5.1.2 Assembly (BOM-2)-Car Boot Model D (Material no.-500000021)

Components of this BOM will be packed as per below

- Assembly (BOM-2)-Car Boot Model D (Material no.-500000021) will be received from the production unpacked and consumed unpacked in the further process to produce FG.

- Assembly (Semi Finished)-Chassis Model D (Material no.-500000023) will be packed into Packaging Big Tote “PACK003” in 1 each.

- Component-Rear Tires (Material no.-500000018) will be packed onto Packaging material special plate “PACK004” 14 EA each and 1 such plate is packed on Pallet “PACK002” supplied by vendor.

5.1.3 Finished Product (Car model D, Material Number 500000027)

Components of this BOM will be packed as per below

- Finished Product (Car model D, Material Number 500000027) will be received after production in the packaging material Finished Car Model D package”PACK006″ in 1 EA

- Component-Electric Wires (Material no.-500000019) will be packed into Packaging material Plastic Drum “PACK001” in 10 KG each and 18 such drums are packed on Pallet “PACK002” supplied by vendor.

- Assembly (Semi Finished)-Car Boot Model D (Material no.-500000021) will be consumed unpacked.

- Component-Petrol (Material no.-500000026), will be packed into Packaging material Bottle “PACK005” in 4 L each.

- Component-Engine Assembled (Material no.-500000009) will be packed onto Packaging material special plate “PACK004” 1 EA each.

Create all the packaging materials as per details

We have created now all the 6 packaging materials

Now we will use the above packaging information in several scenarios

Image by vectorpocket on Freepik